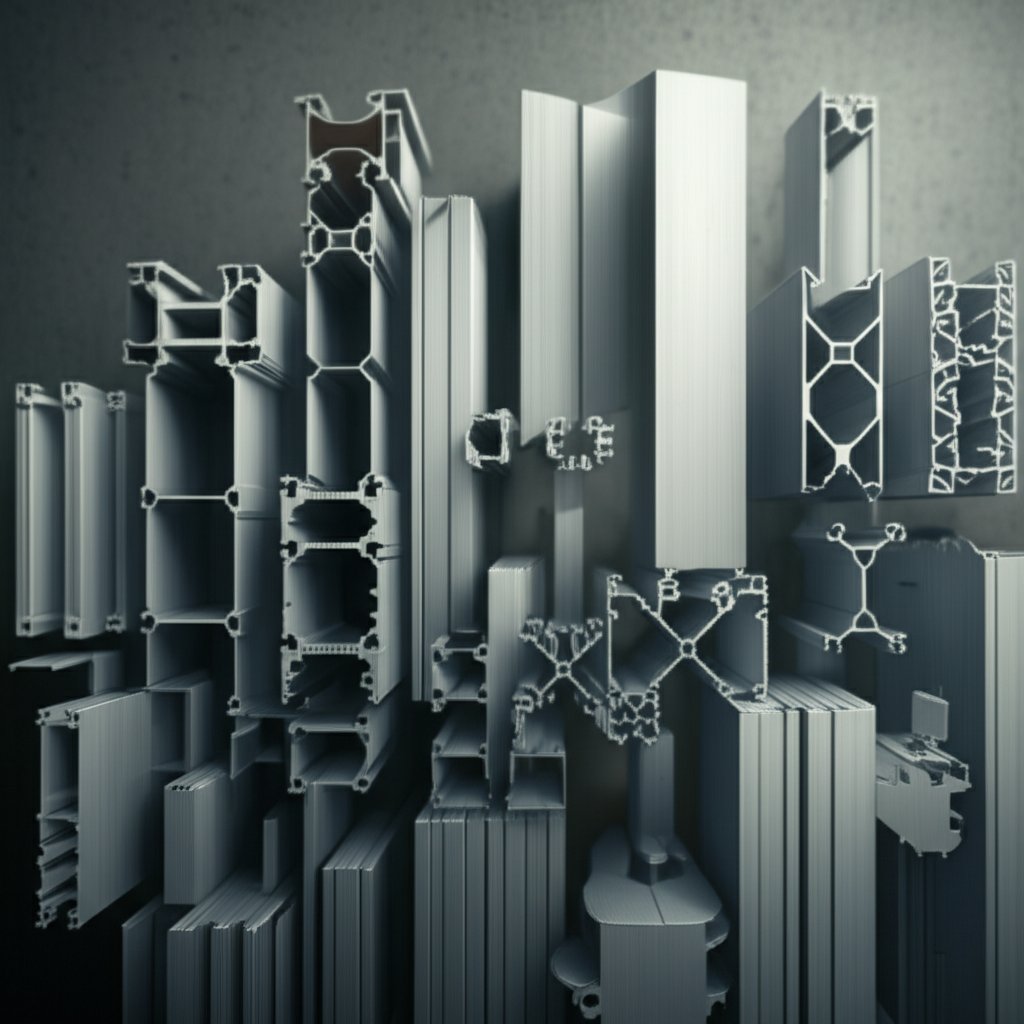

Ever looked at the sleek frame of a window, the sturdy railings on a balcony, or the cooling fins on an LED light fixture and wondered how these precisely shaped components are made? Chances are, you’re seeing the results of aluminum alloy extrusion. From the construction of skyscrapers to the interiors of modern vehicles and even the workbenches in factories, extruded aluminum is everywhere—quietly powering innovation and convenience in our daily lives.

But what exactly is aluminum extrusion, and why has it become such a cornerstone in manufacturing?

Why is this process so valuable? The answer lies in its unique combination of versatility, efficiency, and cost-effectiveness:

These benefits explain why aluminum extrusion applications are so widespread—think of ladders, solar panel frames, machine guards, trade show displays, and even the structural supports inside RVs and trailers. The method’s adaptability and the inherent qualities of aluminum make it the material of choice for countless industries, as highlighted in this blog post.

In this essential guide, we’ll walk you through all the key aspects of aluminum alloy extrusion, including:

By the end of this guide, you’ll have a clear understanding of why aluminum alloy extrusion is a driving force behind modern manufacturing—and how you can leverage its advantages for your next project.

Ever wondered how a solid block of aluminum transforms into the sleek window frames, sturdy rails, or lightweight automotive parts you see every day? The answer lies in the aluminum extrusion process—a fascinating blend of science and engineering that turns raw material into precisely shaped profiles for countless applications.

Imagine decorating a cake with icing. You fill a piping bag, then squeeze it so the icing is forced through a shaped nozzle, emerging in the exact form you want. The aluminum extrusion process works on the same principle: a heated aluminum billet (think of it as a large, solid cylinder) is pushed through a die—essentially a steel disk with an opening shaped like the desired profile. The aluminum emerges in a continuous piece, perfectly matching the die’s cross-section.

Not all extrusion is created equal. There are two main methods—each with its own mechanics and advantages:

| Method | How It Works | Key Features |

|---|---|---|

| Direct Extrusion | The die is stationary, and a ram pushes the heated billet through the die’s opening. |

|

| Indirect Extrusion | The billet stays still, while the die moves toward it, forcing the metal through the opening. |

|

The choice between direct vs indirect extrusion depends on the desired profile, material properties, and production efficiency.

Aluminum extrusion isn’t just about pressure—it’s also about heat. The two primary temperature-based methods are:

For most projects, hot extrusion is the go-to method because it balances formability, strength, and cost-effectiveness. The elevated temperatures make it possible to create both simple and highly complex profiles, supporting the wide range of aluminum extrusion applications seen in architecture, transportation, electronics, and more.

Understanding the basics of the aluminum extrusion process helps you make better choices when designing or specifying parts. Whether you need a simple bar or a custom heat sink with intricate fins, knowing how extrusion works—and the differences between direct vs indirect extrusion or hot vs cold methods—empowers you to collaborate effectively with suppliers and engineers.

Next, let’s break down the step-by-step manufacturing cycle, so you can see exactly how your design comes to life from billet to finished profile.

Ever wondered what really happens between a raw aluminum billet and the finished, perfectly shaped profile you see in construction, transportation, or electronics? The answer lies in a carefully orchestrated sequence known as the extrusion manufacturing cycle. Each step is essential to ensure the quality, strength, and precision of the final product. Let’s break down the aluminum extrusion process steps in a way that’s easy to visualize and understand.

Imagine the journey of an aluminum billet—starting as a simple cylinder and ending as a custom-engineered profile. Here are the key stages, from preparation to finishing:

1. Die Preparation

The process begins with the design and machining of a steel die, which shapes the aluminum into the desired cross-sectional profile.

Before use, the die is preheated (typically to 450–500°C) to promote even metal flow and extend die life. This step ensures consistency and minimizes defects in the final profile.

2. Billet Preparation and Preheating

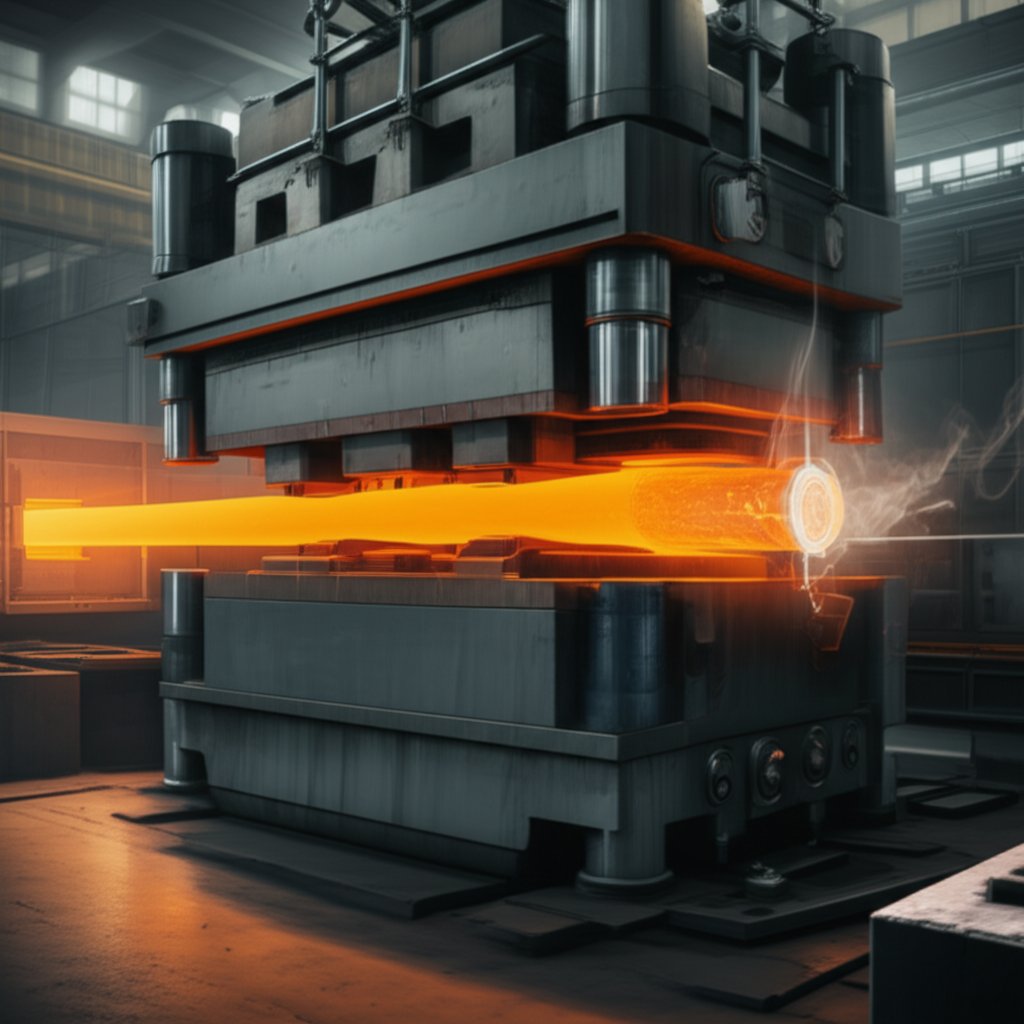

Aluminum billets—solid cylinders cut from longer logs—are preheated in ovens to 400–500°C. This temperature makes the metal malleable without melting it, ensuring it can be extruded smoothly.

Lubrication is applied to both the billet and the extrusion ram to reduce friction and prevent sticking during the pressing process.

3. Extrusion

The preheated billet is loaded into the extrusion press. Using a hydraulic ram (which can apply up to 15,000 tons of pressure), the billet is forced into a container and pressed against the die.

Under immense pressure, the aluminum flows through the die opening, emerging as a continuous profile with the desired cross-section.

4. Quenching and Cooling

As the extruded profile exits the press, it’s immediately cooled—usually by fans or a water bath. This rapid cooling, known as quenching, helps set the metal’s properties and prevents unwanted changes in microstructure.

The profile moves along a runout table to maintain alignment and ensure even cooling.

5. Shearing to Table Length

Once the extrusion reaches the full length of the runout table, a hot saw shears it into manageable segments (typically 8–24 feet long).

At this point, the extrusions are still warm and not fully hardened.

6. Cooling to Room Temperature

The sheared profiles are transferred to a cooling table, where they remain until they reach room temperature. This ensures stability before further handling.

7. Stretching and Straightening

During extrusion and cooling, profiles may develop minor twists or bends. Each piece is gripped at both ends and stretched to remove these distortions, ensuring dimensional accuracy and aligning the internal grain structure for added strength.

8. Cutting to Final Length

After straightening, extrusions are moved to a finish saw and cut to the exact lengths required by the customer—anywhere from a few inches to several feet.

9. Heat Treatment (Aging)

For alloys that require enhanced mechanical properties, the profiles are placed in aging ovens for heat treatment (typically to T5 or T6 tempers). This step increases strength and hardness by accelerating the alloy’s aging process.

10. Finishing and Fabrication

Depending on the application, extrusions may undergo additional processes such as anodizing, painting, powder coating, or machining. These finishing steps enhance appearance, improve corrosion resistance, and allow for tight dimensional tolerances.

Fabrication operations—like drilling, punching, or tapping—can be performed to achieve the final, ready-to-assemble product.

Every phase in the extrusion manufacturing cycle is connected. Skipping or rushing a step can compromise the final product’s performance, dimensional accuracy, or surface quality. For example, improper cooling can lead to internal stresses, while inadequate stretching may leave profiles slightly bent—issues that can affect assembly or long-term durability.

By understanding these aluminum extrusion process steps, you’ll be better equipped to design, specify, or source extruded components that meet your exact requirements. Next, we’ll explore how choosing the right alloy at the outset can make all the difference in performance and cost for your project.

When you’re planning a new product or component, the question often comes up: Which aluminum extrusion alloy should I use? With so many options available, making the right choice can feel overwhelming. The answer depends on your project’s specific needs—strength, corrosion resistance, machinability, appearance, and more. Let’s break down the essentials of aluminum alloy selection and help you navigate the options.

Imagine designing a high-performance bicycle frame, a heat exchanger, or architectural trim. Each application has unique requirements, and the properties of the alloy you choose will directly impact the product’s strength, durability, workability, and even its final cost. While pure aluminum is very ductile, adding other elements (like magnesium, silicon, copper, or zinc) tailors the metal’s properties for specific uses. However, higher concentrations of alloying elements can make extrusion more challenging and sometimes increase costs.

Before you dive into specific alloys, ask yourself:

By prioritizing these requirements, you can quickly narrow down your options among the many aluminum extrusion alloys available.

Aluminum alloys for extrusion are grouped by series, each defined by its main alloying element. Here’s a comparison to help you match alloy properties to your application:

| Series | Main Alloying Element | Key Characteristics | Typical Applications |

|---|---|---|---|

| 1xxx | Aluminum (≥99%) | Excellent corrosion resistance, superior workability, good finishing, low strength | Chemical equipment, food handling, liquid containers |

| 2xxx | Copper (Cu) | High mechanical strength, heat treatable, good machinability, lower corrosion resistance | Aerospace, military, structural parts |

| 3xxx | Manganese (Mn) | Moderate strength, good corrosion resistance, good workability, non-heat treatable | Heat exchangers, cooking utensils, chemical equipment |

| 5xxx | Magnesium (Mg) | Moderate to high strength, excellent corrosion resistance (especially marine), good weldability | Marine parts, vehicle panels, pressure vessels |

| 6xxx | Magnesium (Mg) + Silicon (Si) | Good strength, excellent corrosion resistance, superb weldability, balanced formability, heat treatable | Architectural profiles, automotive parts, structural components |

| 7xxx | Zinc (Zn) | Very high strength, heat treatable, good machinability, lower corrosion resistance | Aircraft, high-stress structural parts, sporting equipment |

While the table above covers the most common series, remember that each alloy within a series has its own strengths. For example, 6061 and 6063 are both in the 6xxx series but offer different balances of strength and finish. Also, factors like temper (heat treatment) and secondary processes (such as anodizing or powder coating) can further enhance properties or appearance.

“The best alloy for your product ultimately comes down to the intended application. For exceptional strength, you can use aluminum alloys 2024 and 7075. If you want a versatile alloy that performs well under a wide range of circumstances, 6061 or 6063 may have what you need.”

Choosing the right aluminum extrusion alloy is a balance of performance, processing ease, and cost. By understanding your project’s priorities and matching them to the properties of each alloy series, you’ll set the stage for a successful, cost-effective extrusion project.

Next, we’ll take a closer look at the popular 6000 series alloys—especially 6061 vs 6063—so you can make an even more informed choice for your next design.

When it comes to aluminum alloy extrusion, the 6000 series stands out as the workhorse of the industry. But what makes these alloys so special—and how do you decide between the ever-popular 6061 and 6063 for your next project? Let’s break it down in practical terms, so you can confidently choose the right material for your needs.

Imagine you’re designing a product that needs to be strong, lightweight, and corrosion-resistant—maybe a window frame, a bicycle component, or an architectural railing. The 6000 series aluminum alloys, primarily composed of magnesium and silicon, offer a unique blend of properties ideal for extrusion:

This is why the 6000 series is the most widely used family for aluminum extrusion profiles across industries—from construction to transportation to consumer products.

Both 6061 and 6063 are stars in the 6000 series, but they shine in slightly different ways. Here’s a side-by-side look to help you choose:

| Property | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Main Strength | Higher (Yield: 35 ksi in T6) | Medium (Yield: 25 ksi in T6) |

| Formability & Extrudability | Good, but less extrudable than 6063 | Excellent—ideal for complex, thin-walled profiles |

| Surface Finish | Good, but not as smooth as 6063 | Superior—fine grain structure, great for anodizing |

| Corrosion Resistance | Excellent | Even better—especially in architectural applications |

| Machinability | B (Good) | C (Average) |

| Typical Applications | Structural parts, machinery, automotive, bicycle frames, electronics | Window/door frames, railings, architectural trim, tubing, decorative profiles |

| Common Tempers | T6 (maximum strength), T4, O | T5 (good balance), T6 |

It’s also worth noting that 6063 can be extruded into thinner walls and more intricate designs than 6061, making it a favorite for challenging custom profiles.

The subtle differences between 6061 vs 6063 aluminum extrusion can have a big impact on your project’s performance, cost, and appearance. That’s why it pays to collaborate with a supplier who understands the nuances of alloy selection, tempering, and finishing.

For example, an experienced manufacturer like Shengxin Aluminum can help you:

Ultimately, the right partnership ensures your aluminum extrusion project runs smoothly from concept to completion—no matter how complex your requirements.

Next up, we’ll dive into how to design both standard and custom extrusion profiles, with actionable tips to make your ideas a reality.

Ever wondered whether you should choose a standard aluminum profile or design something custom for your next project? When it comes to aluminum alloy extrusion, the answer depends on your application’s needs, budget, and timeline. Let’s break down the differences between standard and custom profiles, and then dive into practical aluminum profile design tips that can help you get the best results—no matter your choice.

Imagine you’re building a modular display system, a structural frame for machinery, or the sleek trim for a new architectural project. You’ll likely face this decision:

| Standard Profiles | Custom Profiles |

|---|---|

|

|

Standard profiles are a great fit when your needs match common shapes, ensuring speed and cost savings. But when your project demands precise fit, unique geometry, or integrated features, custom aluminum extrusion profiles unlock new possibilities for performance and efficiency.

Designing for extrusion is all about balancing creativity with practicality. Here are essential tips—backed by industry best practices—to ensure your profile is not just innovative, but also easy and economical to produce:

Still unsure if you need a custom profile? Ask yourself:

If you answered “yes” to any of these, custom aluminum extrusion profiles may deliver better value in the long run—even if the initial investment is higher.

By applying these aluminum profile design tips, you’ll not only create components that meet your technical requirements, but also streamline production and control costs. Next, we’ll look at the critical role of the extrusion die and how it shapes the quality of your finished profiles.

When you picture the perfect aluminum profile—smooth, straight, and dimensionally precise—have you ever wondered what makes such consistency possible? The answer lies at the heart of the extrusion process: the aluminum extrusion die. It’s not just a metal disk; it’s the crucial tool that determines the quality, shape, and performance of every extruded part.

Imagine the die as a precision mold. As heated aluminum is forced through it under immense pressure, the metal takes on the exact shape of the die’s opening. Every contour, angle, and surface finish you see on the final product is a direct reflection of the die’s design and construction.

But why is extrusion die quality so vital? Here’s what’s at stake:

Not all profiles are created equal—and neither are their dies. Choosing the right die type is essential for both quality and cost:

| Die Type | Description | Common Applications |

|---|---|---|

| Solid Die | Produces profiles without internal cavities. Simpler design, lower cost. | Bars, angles, channels, structural connectors |

| Hollow Die | Creates profiles with one or more internal voids using mandrels and bridges. | Tubes, window frames, automotive door frames |

| Semi-Hollow Die | Combines features of both; enables complex shapes with partial cavities. | Profiles with both solid and hollow sections, custom architectural elements |

Each die type comes with its own set of engineering challenges. For example, hollow and semi-hollow dies require careful design to manage material flow and ensure weld integrity where streams of aluminum rejoin inside the die.

Sounds complex? That’s because it is. The die must withstand pressures up to 15,000 tons while maintaining precise shape and alignment. That’s why most dies are crafted from high-grade tool steels like H13, prized for their toughness, thermal stability, and resistance to wear.

Key factors in die quality include:

It might be tempting to cut costs on tooling, but the die is not the place to compromise. Here’s why:

In short, the aluminum extrusion die is the silent hero behind every successful extrusion project. Its quality and design directly influence every aspect of your final product—from appearance and strength to cost and performance. As you move forward with your own designs, keep in mind that investing in die quality is investing in your project’s success.

Next, we’ll guide you through how to evaluate and select the best extrusion manufacturer, ensuring your profiles are made to the highest standards from start to finish.

When you’re ready to turn your aluminum extrusion design into reality, choosing the right manufacturing partner can make or break your project. But with so many options out there, how do you confidently make the best aluminum extrusion manufacturer selection? Imagine investing months in design, only to face delays, inconsistent quality, or unexpected costs because your supplier wasn’t up to the task. To avoid these headaches, it pays to follow a proven checklist—one used by industry professionals—to evaluate and select a manufacturer that fits your needs perfectly.

Sounds complex? It doesn’t have to be. Use the following aluminum extrusion supplier checklist to guide your decision:

| Criteria | What to Look For | Why It Matters |

|---|---|---|

| Industry Experience & Track Record | Years in business, portfolio of completed projects, positive client feedback, experience with your industry/application | Experienced manufacturers can anticipate challenges and deliver consistent results, even for complex or custom projects. |

| Production Capabilities | Modern equipment, range of press sizes, ability to produce both standard and custom profiles, support for various alloys | Ensures your supplier can handle your design specifications, volume requirements, and alloy needs without compromise. |

| Vertical Integration | In-house control of the entire process—from billet casting and extrusion to finishing, fabrication, and assembly | Reduces lead times, improves quality control, and streamlines communication, as seen with vertically integrated suppliers. |

| In-House Finishing & Deep Processing | Anodizing, powder coating, machining, CNC, custom fabrication, and assembly services | Having these services under one roof means faster turnaround, better quality oversight, and fewer logistics headaches. |

| Quality Control & Certifications | Robust QC procedures, ISO or equivalent certifications, traceability, and documented inspection protocols | Demonstrates commitment to delivering consistent, high-quality products that meet industry standards. |

| Material Sourcing & Alloy Selection | Access to a wide range of alloys, ability to advise on best fit for your application | Ensures your profiles meet both performance and budget goals. |

| Transparent Pricing & Customer Support | Clear cost breakdowns, honest lead time estimates, responsive support, willingness to provide references | Prevents unpleasant surprises and builds trust for long-term collaboration. |

| Sustainability & Ethical Practices | Commitment to environmental standards, energy-efficient processes, and responsible sourcing | Increasingly important for projects with corporate or regulatory sustainability goals. |

Imagine a supplier who controls every step—from raw billet to finished, assembled product. This vertical integration means:

Vertically integrated manufacturers like Shengxin Aluminum exemplify this approach, offering comprehensive capabilities: from extrusion and finishing to deep processing and assembly—all under one roof. This not only streamlines your project but also ensures tighter quality control and better communication throughout the process.

Before you commit, ask yourself (and your potential supplier):

By methodically working through this aluminum extrusion supplier checklist, you’ll gain the clarity and confidence needed to select a partner who can deliver on your vision—on time, on budget, and to the highest standards.

Next, we’ll explore the commercial and logistical factors to consider when sourcing aluminum extrusions, especially when working with suppliers across regions or internationally.

Ready to bring your design to life and searching for aluminum alloy extrusion for sale? Whether you’re a seasoned engineer or a first-time buyer, sourcing extrusions—especially from international suppliers—can feel like a maze of choices and trade-offs. What should you watch for to make sure your project stays on time, on budget, and meets your quality standards? Let’s break down the most important commercial and logistical factors, using real-world examples and practical tips.

It’s tempting to focus on the lowest quoted price, but the real cost of your extrusions is more than just the sticker tag. Here’s what you need to consider for an accurate picture:

Many extrusion suppliers, especially those overseas, have minimum order requirements—often ranging from 500 to 1,000 pounds per profile. This can impact your ability to prototype or make small production runs. However, some specialized manufacturers offer flexible options for low-volume orders, which is ideal for prototyping or pre-production phases. Always clarify minimums before committing, and align your order size with your project’s stage to avoid excess inventory or unnecessary costs.

Thinking about sourcing aluminum alloy extrusion China? China is a global leader in aluminum extrusion manufacturing, offering competitive pricing and a wide range of capabilities. But is it always the best fit for your needs? Consider the following:

| Region | Pros | Cons |

|---|---|---|

| China |

|

|

| Domestic/Regional (e.g., US, EU) |

|

|

Ever had a part arrive that didn’t fit—or worse, failed in use? Clear, detailed communication with your supplier is essential, especially when working across borders. Here’s how to keep your project on track:

By keeping these key factors in mind, you’ll be well-equipped to navigate the complexities of sourcing aluminum alloy extrusions—whether you’re buying locally or exploring options overseas. Next, we’ll wrap up with a summary of the main takeaways and how to leverage extrusion for innovation and efficiency in your next project.

When you step back and look at the world around you, it’s remarkable how many everyday innovations owe their existence to aluminum alloy extrusion. From the windows that let in natural light to the silent strength inside your car’s frame or the efficient cooling of your electronics, extruded aluminum quietly shapes modern life. But what makes this process so valuable—and how can you make the most of its advantages in your own projects?

As you’ve seen throughout this guide, getting the most from aluminum extrusion isn’t just about picking a profile and pressing go. It’s about making informed decisions at every step:

Imagine the next generation of products—lighter vehicles, energy-efficient buildings, smarter electronics—each made possible by the unique aluminum alloy extrusion benefits you’ve learned about here. As industries push for greater performance and sustainability, extrusion stands out as a proven solution for innovation.

Ready to take your ideas further? Collaborating with expert partners can make all the difference. Companies like Shengxin Aluminum offer comprehensive aluminum extrusion solutions, from alloy selection and custom design to finishing and deep processing—empowering you to bring even the most ambitious projects to life with confidence. Please check the blog post first,it may help you a lot.

In the end, mastering aluminum alloy extrusion isn’t just about understanding a process—it’s about unlocking new possibilities for your business, your products, and the world around you. With the right knowledge and the right partners, you’re well-equipped to leverage extrusion for greater efficiency, innovation, and long-term success.

Yes, most aluminum alloys can be extruded into a variety of shapes and sizes. However, the specific alloy, profile complexity, and tolerance requirements will affect the extrudability and final quality. Selecting the right alloy and working with an experienced manufacturer ensures successful extrusion tailored to your project's needs.

The 6000 series, particularly 6061 and 6063, are the most popular choices for aluminum extrusion due to their excellent combination of strength, corrosion resistance, and workability. 6061 is favored for structural strength, while 6063 is ideal for intricate profiles and superior surface finish. The best alloy depends on your application's performance and appearance requirements.

6061-T6 is a commonly extruded aluminum alloy, valued for its high strength-to-weight ratio and versatility. It's widely used in demanding applications like aerospace, automotive, and machinery, where both strength and lightweight properties are essential.

The aluminum extrusion process involves several steps: die preparation, billet preheating, extrusion through a die, cooling, stretching, cutting to length, heat treatment, and finishing. Each stage is crucial for achieving precise profiles with optimal mechanical properties and surface quality.

Look for manufacturers with proven industry experience, comprehensive production capabilities, in-house finishing and deep processing, quality certifications, and transparent customer support. Vertically integrated suppliers like Shengxin Aluminum can offer end-to-end control, ensuring consistent quality and efficient project delivery.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360