Have you ever wondered why airplanes are built with aluminium instead of steel, or why beverage cans feel so light in your hand? The answer often comes down to a fundamental property called mass density. But what exactly does this mean, especially when we talk about the mass density of aluminium?

Mass density is a simple but powerful concept: it tells us how much mass is packed into a given volume of material. Imagine two cubes of the same size—one made of aluminium, the other of copper. If you weigh them, you'll notice the aluminium cube is much lighter. That's because aluminium has a lower mass density than copper, meaning less mass is concentrated in the same amount of space (ACS Chemistry).

But why is the aluminium density g/cm3 so important? In fields like aerospace, automotive, and construction, knowing the density of aluminium helps engineers design lighter, more efficient products without sacrificing strength. This property is key to reducing energy use, improving fuel efficiency, and even lowering costs across a wide range of applications.

In this article, we'll break down:

So, whether you're an engineer, student, or just curious about materials, understanding the mass density of aluminium is your first step toward appreciating why this metal is so widely used—and why it continues to shape our modern world.

When you pick up a metal object and notice how heavy or light it feels, you’re actually experiencing the effects of mass density. But what is mass density, really? And how does it help us understand materials like aluminium?

Mass density is a scientific way of describing how much “stuff”—or matter—is packed into a certain amount of space. In more technical terms, it’s the amount of mass per unit volume of a substance. The mass density formula is:

Density (ρ) = Mass (m) / Volume (V)

This simple equation tells us that if you know how much something weighs (its mass) and how much space it takes up (its volume), you can calculate its density. It’s a characteristic property, meaning each pure substance has its own unique density.

Depending on where you’re working or what you’re measuring, you’ll see density expressed in different units. Here are the most common:

Regardless of the units, the principle remains the same: density compares mass to volume.

It’s easy to mix up density and weight, but they’re not the same thing. Mass is the measure of how much matter is in an object, while weight is the force of gravity pulling on that mass. Think of it this way: your mass stays the same whether you’re on Earth or the Moon, but your weight changes because the Moon’s gravity is weaker (UCLA Physics).

This distinction is crucial in science and engineering, especially when comparing materials or designing for different environments.

Why do some materials feel heavier than others, even if they’re the same size? The answer lies in their atomic structure. The density of a substance depends on:

For example, aluminium has lighter atoms and a different arrangement compared to copper. That’s why a cube of aluminium is lighter than a same-sized cube of copper, even though both are solid metals. The unique combination of atomic mass and structure gives each element its characteristic density.

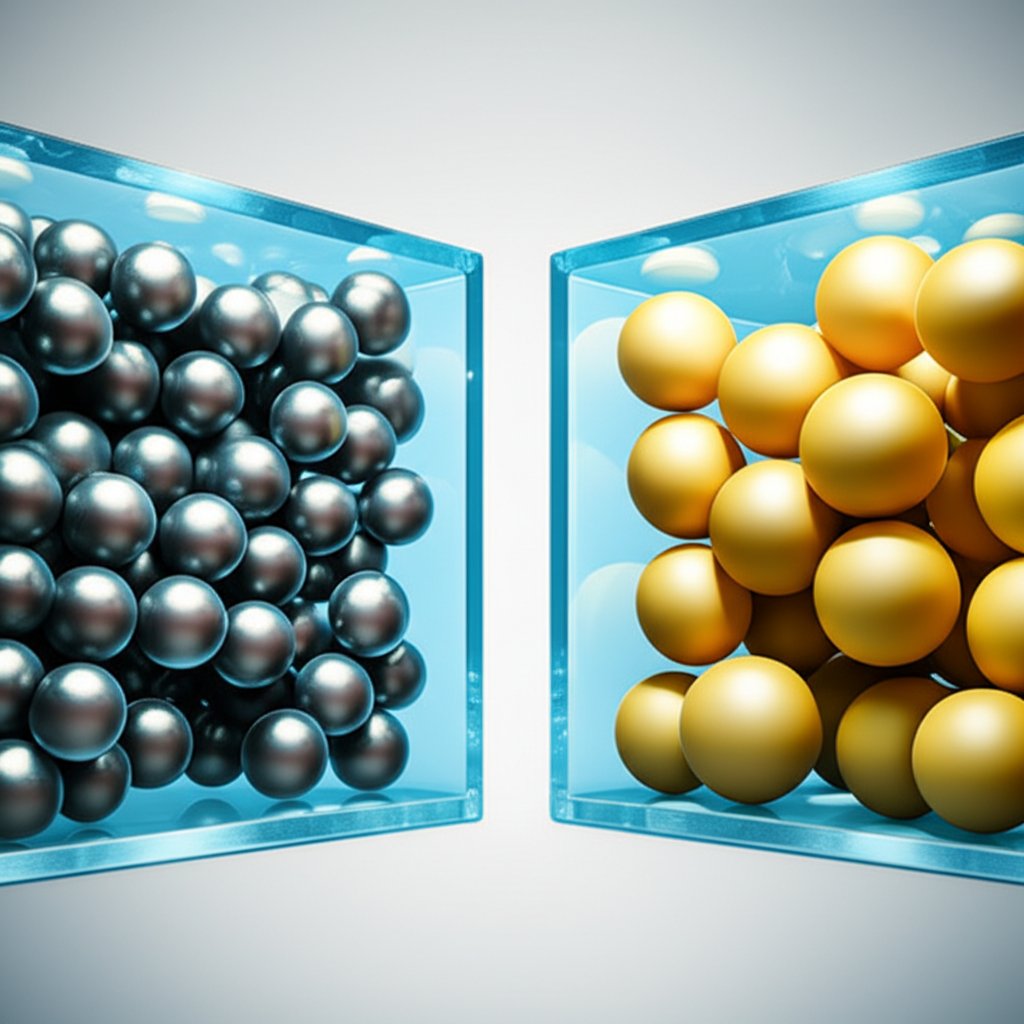

Imagine two boxes of equal size. Fill one with large, lightweight balls (like ping-pong balls) and the other with small, heavy marbles. Even though the boxes are the same size, the one with marbles will be much heavier—that’s higher density. This is similar to how different atomic arrangements and masses create different densities for each material.

Now that you understand the basics of mass density and how it’s determined, let’s explore the specific values for aluminium and how they can vary based on composition and conditions.

When you see a lightweight ladder, a soda can, or the wing of an airplane, you’re looking at the unique advantages of aluminium’s mass density in action. But what exactly is the standard mass density of pure aluminium, and how do common aluminium alloys compare?

Let’s start with the basics. The mass density of pure aluminium at room temperature is widely recognized as 2.70 g/cm³ (or 2700 kg/m³). This means that a block of pure aluminium with a volume of one cubic centimeter weighs just 2.7 grams. For most engineering and scientific calculations, this is the go-to value. Aluminium’s relatively low density—about one third that of steel—makes it a favorite for applications where weight savings are crucial.

Sounds simple? Here’s where things get interesting: in real-world applications, pure aluminium is rarely used on its own. Instead, it’s combined with other elements—like copper, magnesium, silicon, and zinc—to form aluminium alloys. These additions are designed to boost strength, corrosion resistance, or other properties, but they also affect density.

Generally, the density of aluminum alloys ranges from about 2.64 to 2.90 g/cm³ (or 2640 to 2900 kg/m³), depending on the alloying elements and their proportions. Even small changes in composition can have a noticeable effect on the final density, which is why engineers carefully select alloys based on their specific needs.

To make things easier, here’s an aluminium alloy density chart that compares the standard values for pure aluminium and some of the most commonly used alloys:

| Alloy / Series | Major Alloying Elements | Typical Density (g/cm³) | Notes |

|---|---|---|---|

| Pure Aluminium (1xxx) | None (≥99% Al) | 2.70 | Reference value; soft and ductile |

| 1100 (1xxx Series) | None | 2.70 | Very similar to pure Al |

| 2024 (2xxx Series) | Copper | 2.78 | High strength; aircraft structures |

| 5052 (5xxx Series) | Magnesium | 2.68 | Corrosion-resistant; marine use |

| 6061 (6xxx Series) | Magnesium, Silicon | 2.70 | Versatile; structural components |

| 7075 (7xxx Series) | Zinc, Magnesium | 2.81 | Very high strength; aerospace |

| 8006 (8xxx Series) | Iron, Silicon | 2.89 | Foil and packaging alloys |

As you can see, the density of aluminium alloys can shift up or down depending on their makeup. For example, 5052 (with magnesium) is slightly lighter than pure aluminium, while 7075 (with zinc and magnesium) is heavier. These differences, though seemingly minor, can have a big impact when you’re designing products that need to be both strong and lightweight.

Now that you understand how alloying elements influence the density of aluminium, let’s explore what factors—like temperature, processing, and impurities—can further affect these values in real-world situations.

Ever wondered why the density of aluminium sometimes varies from one product to another? Or why engineers don’t always rely on a single number when designing with this metal? The answer lies in a handful of key factors that can influence the mass density of aluminium—sometimes in subtle but important ways. Let’s break down the main factors affecting aluminium density and see how they come into play in real-world applications.

While the standard density of pure aluminium is about 2.70 g/cm³ (2700 kg/m³), several variables can cause this value to shift. Understanding these influences is crucial for precise engineering, quality control, and selecting the right material for your project.

Imagine you’re designing a lightweight bike frame or a spacecraft panel. You can’t just grab a single density value from a chart—you need to account for alloy selection, processing methods, operating temperatures, and even the tiniest impurities. Each of these factors can cause aluminium density variation that affects the final product’s weight, strength, and performance.

By understanding these variables, engineers and designers can make smarter choices, ensuring their aluminium components meet exacting standards—whether for speed, efficiency, or durability. Next, let’s explore how density is actually measured and calculated in both the lab and on the factory floor.

Ever wondered how scientists and engineers actually determine the mass density of aluminium? Whether you’re working in a lab, on the shop floor, or just curious at home, there are several reliable ways to measure this fundamental property. Let’s break down the most common methods—some simple, some more advanced—so you can see how mass density calculation aluminium is done in practice.

At its core, density is calculated using a straightforward formula:

Density (ρ) = Mass (m) / Volume (V)

Sounds simple, right? But the trick is measuring both mass and volume accurately, especially if your aluminium object isn’t a perfect cube or cylinder. Here’s where different techniques come into play.

When you have an irregularly shaped piece of aluminium, the water displacement method—based on Archimedes’ Principle—is a go-to technique. Here’s how to measure aluminium density using this approach:

Tip: If the object can’t be put in water (due to corrosion risk or size), other liquids like ethanol or acetone can be used, but always follow safety guidelines.

If your aluminium sample is a simple shape—like a rod, plate, or block—you can measure its dimensions with calipers or rulers. Here’s the process:

This method is quick, but only accurate for objects with precise, regular dimensions.

For high-accuracy needs, especially with powders or small samples, scientists use a pycnometer—a specialized glass flask with a tight-fitting stopper. The steps are:

This method minimizes errors from trapped air and is excellent for very small or granular samples.

For the most precise measurements, especially in research, X-ray diffraction techniques are used. Here’s a simplified outline:

This method is mainly used in scientific studies and quality control of high-purity materials.

| Method | Best For | Key Steps | Typical Accuracy |

|---|---|---|---|

| Water Displacement (Archimedes) | Irregular shapes, general use | Weigh in air, submerge, measure volume change | High (±0.01 g/cm³) |

| Geometric Measurement | Regular shapes | Measure dimensions, calculate volume, weigh | Moderate to high |

| Pycnometer | Powders, small samples | Weigh with/without sample, fill with liquid | Very high |

| X-ray Crystallography | Pure crystals, research | X-ray diffraction, calculate lattice parameters | Extremely high |

So, whether you’re measuring a soda can, a machined part, or a scientific sample, you now have a toolkit for how to measure aluminium density with confidence. Each method has its strengths, depending on accuracy needs and sample type. Next, let’s see why understanding aluminium’s density is so crucial in real-world industries and how it shapes the products we use every day.

When you imagine an airplane soaring overhead, a sleek electric car gliding by, or the ease of lifting a can of your favorite drink, you’re witnessing the impact of aluminium’s unique mass density. But why is this property such a game-changer across so many industries? Let’s explore how aluminium density applications drive innovation, efficiency, and performance in the products and infrastructure that shape our lives.

It’s not just about being light—aluminium alloys deliver impressive strength for their weight. This high strength-to-weight ratio is what sets aluminium apart from many other metals. For example, while a steel part might be stronger in absolute terms, an aluminium part can often achieve the needed performance at a fraction of the weight, which is crucial for applications where every ounce matters.

As industries demand ever more specialized and efficient products, the need for expertly engineered aluminium profiles for industry grows. This is where advanced manufacturers like Shengxin Aluminum come in. With large-scale production capabilities and expertise in alloy development, Shengxin Aluminum produces custom profiles tailored for sectors where density and performance are critical—such as new energy vehicles, rail transit, and high-tech construction projects.

By leveraging advanced alloy compositions and cutting-edge extrusion technology, Shengxin Aluminum ensures each profile meets stringent industry standards for strength, weight, and durability. Their capacity to deliver both standard and highly customized solutions makes them a trusted partner for clients with demanding density and performance requirements.

Ultimately, the mass density of aluminium is more than just a number on a datasheet—it’s a property that empowers engineers, architects, and designers to create lighter, safer, and more sustainable products. Whether it’s the next generation of electric vehicles or the smart devices in your hand, aluminium’s unique balance of lightness and strength is helping to shape a more efficient and innovative future. In the next section, we’ll see how aluminium’s density stacks up against other common metals, offering even greater context for its widespread use.

When you’re choosing materials for a project—whether it’s building a bridge, designing a lightweight vehicle, or manufacturing consumer electronics—the question often comes up: how does aluminium’s density compare to other popular metals? Let’s walk through a practical, side-by-side look at aluminium vs steel density and more, so you can see why aluminium’s low density is such a game-changer in modern engineering.

Imagine you need to build a structure that’s both strong and easy to move. Would you choose a heavy, dense metal or a lighter alternative? The answer depends on your priorities, but in applications where weight reduction is critical—think aerospace, automotive, or portable electronics—aluminium’s low density often tips the scales in its favor. Lighter materials mean easier handling, reduced transport costs, and improved energy efficiency.

To make things clear, here’s a metal density comparison table featuring aluminium and other widely used metals. Notice how aluminium stands out for its low density, especially when compared to steel, copper, and lead:

| Metal | Typical Density (g/cm³) | Key Characteristic / Application |

|---|---|---|

| Aluminium (Al) | 2.7 | Lightweight; used in aerospace, automotive, packaging |

| Magnesium (Mg) | 1.74 | Lighter than aluminium; used in specialty automotive/aerospace parts |

| Titanium (Ti) | 4.5 | High strength-to-weight ratio; aerospace, medical implants |

| Iron (Fe) | 7.87 | Core element in steel; construction, machinery |

| Steel (Alloy) | ~7.85 | Strong and versatile; construction, automotive, tools |

| Copper (Cu) | 8.96 | Excellent electrical/thermal conductivity; wiring, plumbing |

| Zinc (Zn) | 7.14 | Corrosion-resistant; galvanizing steel, die casting |

| Lead (Pb) | 11.34 | Very dense; batteries, radiation shielding |

As you can see, aluminium is significantly less dense than most structural metals. For example, steel is nearly three times heavier than aluminium for the same volume. This difference is why aluminium is often the top choice for applications where weight savings translate directly into performance, cost savings, or ease of use:

With such a clear density advantage, manufacturers like Shengxin Aluminum are able to design and produce a vast range of aluminium profiles tailored for industries where every gram counts. Shengxin’s advanced extrusion and finishing lines allow for the creation of lightweight yet robust profiles that meet the exacting standards of sectors like new energy vehicles, rail transit, and high-performance construction. Their expertise in alloy selection and processing ensures that you get the optimal balance of weight, strength, and durability—no matter the application.

Of course, density is just one factor in material selection. Strength, corrosion resistance, cost, and recyclability all play important roles. But when it comes to combining lightness with versatility, aluminium’s position in the metal density comparison table is hard to beat. In the final section, we’ll recap the key takeaways and show how understanding aluminium’s density empowers smarter, more innovative engineering choices.

Why does the mass density of aluminium matter so much, and what does it mean for the future of engineering and design? If you’ve the journey through this article, you’ve seen how a single property—density—can shape industries, drive innovation, and even influence the everyday products you use.

Imagine designing a high-speed train, a fuel-efficient electric car, or a lightweight laptop. In each scenario, the significance of aluminium density is clear: lighter materials mean less energy consumption, easier handling, and more flexible designs. By mastering the variables that influence density, engineers and manufacturers can create products that are not only lighter and stronger, but also more cost-effective and environmentally friendly.

As the demand for advanced, lightweight solutions grows, so does the need for reliable partners in aluminium manufacturing. Companies like Shengxin Aluminum bring together deep expertise in alloy development, large-scale production, and precision engineering. Whether you require standard or highly customized aluminium profiles for automotive, rail, construction, or next-generation consumer products, partnering with a leading aluminium profiles manufacturer ensures your projects benefit from the best balance of density, strength, and quality.

In summary, understanding the mass density of aluminium isn’t just a matter of numbers—it’s the key to unlocking lighter, smarter, and more sustainable innovations across industries. If you’re looking to leverage the unique advantages of aluminium in your next project, consider working with manufacturers who combine technical know-how with advanced production capabilities to deliver exceptional results every time.

Aluminium has a standard density of 2.7 g/cm³, which makes it much lighter than most structural metals. This property is a key reason for its widespread use in aerospace, automotive, and packaging industries where reducing weight is crucial.

The mass density of aluminium is approximately 0.1 lb/in³. This low density allows for the production of lightweight components, offering significant advantages in applications like vehicle manufacturing and construction.

Pure aluminium typically has a specific weight of about 2700 kg/m³. This value may vary slightly depending on the alloy composition and manufacturing processes, but it serves as a reliable reference for most engineering applications.

Adding elements such as copper, magnesium, silicon, or zinc to aluminium forms alloys with densities that can be slightly higher or lower than pure aluminium. For example, magnesium can decrease the density, while copper or zinc can increase it. Manufacturers like Shengxin Aluminum tailor alloy compositions for optimal performance in specific industries.

Aluminium's low density enables the creation of lightweight, strong, and energy-efficient products. This is especially valuable in aerospace, automotive, rail transit, and construction sectors. Companies like Shengxin Aluminum leverage this property to produce high-quality profiles that help reduce energy consumption and improve overall performance.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360