Have you ever wondered what happens to a soda can or a piece of kitchen foil when exposed to intense heat? The answer lies in a fundamental property known as the aluminum melting point. While it may sound like a detail best left to scientists, understanding this concept is crucial for anyone involved in engineering, manufacturing, or even everyday household tasks.

So, why is the aluminum melting point so important? Imagine designing an aircraft part, a car engine, or simply choosing cookware for your kitchen. In each case, knowing the exact temperature at which aluminum transitions from solid to liquid can make all the difference between a product that performs flawlessly and one that fails under pressure. For professionals in construction or aerospace, this thermal property is a cornerstone for safe and reliable design. Even in daily life, it ensures that the materials we use can withstand the heat—literally.

But here’s where it gets interesting: not all aluminum is created equal. Pure aluminum melts at a precise temperature, but most of what we encounter in the real world are aluminum alloys—blends of aluminum with other elements like copper or magnesium. These alloys have different, often lower, melting points and a range of properties tailored for specific uses. This difference between pure aluminum and its alloys opens up a world of possibilities—and questions. How do these variations impact the materials you use every day?

Throughout this guide, we’ll break down the science behind the aluminum melting point, explore how it’s measured (including the aluminum melting point in Celsius), and compare pure aluminum to its most common alloys. We’ll also look at how everyday products like cans and foil behave at high temperatures, and wrap up with practical advice for using aluminum safely and efficiently—whether you’re an engineer, a hobbyist, or simply curious.

For a deeper dive into the science and significance of aluminum’s melting point, check out this comprehensive resource: Melting Point of Aluminum: Vital Insights for Innovators.

Ready to explore the fascinating world of aluminum? Let’s start with the scientific fundamentals and see how this simple number shapes the way we build, create, and innovate.

When you hear the term aluminum melting point, you might picture a metal slowly softening and then turning to liquid under intense heat. But did you know that for pure aluminum, this transformation happens at a remarkably precise temperature? Let’s break down what this means—and why it matters for everything from manufacturing to material science.

The pure aluminum melting point is internationally recognized as 660.32°C (1220.58°F). In scientific terms, this is the temperature at which pure, unalloyed aluminum (at least 99.9% purity) shifts from a solid to a liquid state. Imagine holding a bar of pure aluminum and gradually heating it. No matter how thick or thin the piece, once it reaches this exact temperature, it will begin to liquefy—no sooner, no later.

To make this even clearer, here’s a quick reference:

| Measurement Unit | Melting Point |

|---|---|

| Celsius (°C) | 660.32 |

| Fahrenheit (°F) | 1220.58 |

| Kelvin (K) | 933.47 |

Sounds complex? In reality, this number is a physical constant for pure aluminum. That means it doesn’t change, no matter where or how you measure it—assuming you have pure aluminum and standard atmospheric pressure. This consistency is critical for scientists and engineers. It allows them to use pure aluminum as a reference point for calibrating instruments, designing heat treatments, and standardizing industrial processes.

It’s important to note that this precise melting point only applies to aluminum of extremely high purity—think 99.9% or greater. Even small amounts of other elements can lower the melting temperature. For example:

This is why the pure aluminum melting point serves as a baseline. Most aluminum products you encounter—like cans, foil, or structural beams—are alloys, meaning their aluminum melting temperature will be somewhat lower and less precise, typically spanning a range rather than a single value.

Think of the pure aluminum melting point as the "north star" for anyone working with this metal. It’s the benchmark against which all alloys are measured. When engineers develop new aluminum alloys for cars, airplanes, or electronics, they start with pure aluminum’s melting point and then adjust it by adding other elements to achieve specific properties—like increased strength or corrosion resistance.

Understanding this scientific constant is the first step to mastering how aluminum behaves in real-world applications. Next, we’ll explore how temperature scales—Celsius, Fahrenheit, and Kelvin—are used to report and compare these values, making it easy for professionals around the world to stay on the same page.

Ever checked a technical datasheet and wondered why the aluminum melting point is listed in Celsius, Fahrenheit, or even Kelvin? If you’re working internationally or comparing scientific papers, you’ll notice these temperature scales pop up everywhere. Let’s break down what each scale means, why they’re used, and how to easily convert between them when discussing aluminum’s melting temperature.

Imagine you’re reading a research article from Europe—chances are, the aluminum melting point in Celsius will be front and center. But pick up a US manufacturing guide, and Fahrenheit might take the lead. In advanced physics or engineering, you’ll sometimes see Kelvin, especially when discussing thermodynamic calculations or scientific constants. Here’s why these three scales matter:

To make things simple, here’s a handy table you can reference when you need to convert or compare the aluminum melting point Kelvin, Celsius, or Fahrenheit values. These numbers are based on the melting point of pure aluminum:

| Temperature Scale | Melting Point |

|---|---|

| Celsius (°C) | 660.32 |

| Fahrenheit (°F) | 1220.58 |

| Kelvin (K) | 933.47 |

For example, if you’re designing a process that involves melting aluminum in a US foundry, you’ll probably set your furnace to just above 1220.58°F. But if you’re collaborating with a global engineering team, referencing 660.32°C will keep everyone on the same page. And if you’re modeling heat transfer or phase changes in a physics simulation, you’ll likely use 933.47 K for accuracy.

Understanding these scales isn’t just academic—it’s practical. Using the right unit ensures clear communication, precise temperature control, and successful results in any aluminum-related project. In the next section, we’ll explore how these melting points play out in real-world items, like aluminum foil, and why thickness and form can affect how aluminum behaves when heated.

Ever wondered, “Does aluminum foil melt at the same temperature as a thick block of aluminum?” If you’ve wrapped potatoes for baking or lined a grill, you might have noticed that the foil holds up well—until it’s exposed to a direct flame. Let’s clear up the mystery behind the aluminum foil melting point and explore what really happens when you heat this everyday material.

In scientific terms, aluminum foil melts at approximately 660°C (1220°F), just like bulk aluminum. That’s because foil is made from the same metal, only rolled to a thickness thinner than a human hair. The process of making foil doesn’t change the fundamental chemistry—so whether it’s a heavy ingot or a delicate sheet, the melting point remains the same (source).

Here’s where things get interesting: while the melting point doesn’t change, the way foil responds to heat can be very different due to two key factors:

| Scenario | What Happens? |

|---|---|

| Baking or Roasting | Foil stays solid and stable |

| Direct Contact with Flame | Foil may oxidize, develop holes, or "vanish"—rarely forms a molten puddle |

So, does aluminum foil melt at the same temperature as bulk aluminum? Yes—but in everyday use, you’re far more likely to see it oxidize or break down before it turns to liquid. This is why foil is so reliable for cooking and insulating, yet needs careful handling around open flames or extreme heat.

Understanding these subtle differences is key for safe and effective use of aluminum foil in the kitchen or workshop. Next, we’ll look at another familiar product—aluminum cans—and see how alloy composition and coatings create a slightly different melting story.

When you toss an empty soda can into the recycling bin, have you ever wondered what happens if that can is exposed to extreme heat? Or why it doesn't simply melt in your kitchen oven? The answer lies in the fascinating science of aluminum alloys—especially the ones used for beverage cans. Let's explore how the aluminum can melting point is determined not by pure aluminum, but by carefully engineered alloy blends.

Most people assume that beverage cans are made from pure aluminum, but that's not the case. Instead, manufacturers use specialized alloys—most commonly Aluminum 3004 and its close cousin, 3104. These alloys are chosen for their perfect balance of strength, formability, and corrosion resistance, making them ideal for thin-walled containers that must withstand both internal pressure and external handling.

Unlike pure aluminum—which melts at a precise 660.32°C (1220.58°F)—aluminum alloys like 3004 have a melting range. This means they don't transform instantly from solid to liquid, but instead gradually soften and melt across a span of temperatures. For Aluminum 3004, the melting range is typically around 630°C (1166°F), slightly lower than pure aluminum due to the presence of alloying elements.

| Material | Melting Point/Range (°C) | Key Alloying Elements |

|---|---|---|

| Pure Aluminum | 660.32 | None (99.9%+ Al) |

| Aluminum 3004 Alloy | ~630 | Manganese, Magnesium |

This aluminum alloy melting range is beneficial for manufacturing. Why? Because it allows the metal to be formed, shaped, and sealed at slightly lower temperatures, reducing energy consumption and minimizing the risk of damaging the thin can walls during production. It also makes recycling more efficient, as cans can be melted down at lower temperatures compared to pure aluminum products.

Here's something you might not expect: every aluminum can is lined with protective coatings—both inside and out. These coatings prevent the beverage from reacting with the metal and extend shelf life. But what happens to these layers when cans are exposed to high heat?

So, when you see aluminum cans being recycled, the process involves first burning off these coatings, then melting the alloyed metal at its specific range. This two-step thermal treatment is crucial to maintain the quality and safety of recycled aluminum products.

For consumers, this means your beverage cans are safe in any kitchen or household scenario—they won't melt or deform at typical cooking or baking temperatures. For manufacturers and recyclers, understanding the precise aluminum can melting point and the behavior of coatings ensures efficient, sustainable, and high-quality production cycles.

Next, we'll dive deeper into how alloying—adding elements like magnesium, silicon, or copper—further tunes the melting range and properties of aluminum for a wide variety of industrial and engineering applications.

Ever wondered why aluminum used in airplanes, cars, or electronics isn’t the same as the pure metal you might imagine? Or why two pieces of aluminum can behave very differently when exposed to heat? The answer lies in alloying—a process that transforms basic aluminum into a family of high-performance materials with tailored properties and, crucially, a unique aluminum melting range.

Aluminum alloys are created by combining aluminum with other elements. Sounds complex? Think of it like baking a cake: by adding ingredients such as magnesium, silicon, or copper, you change the texture, flavor, and performance of the final product. In the world of metals, alloying is used to:

But here’s where it gets interesting for anyone working with heat: alloying elements also have a profound impact on the aluminum alloy melting point.

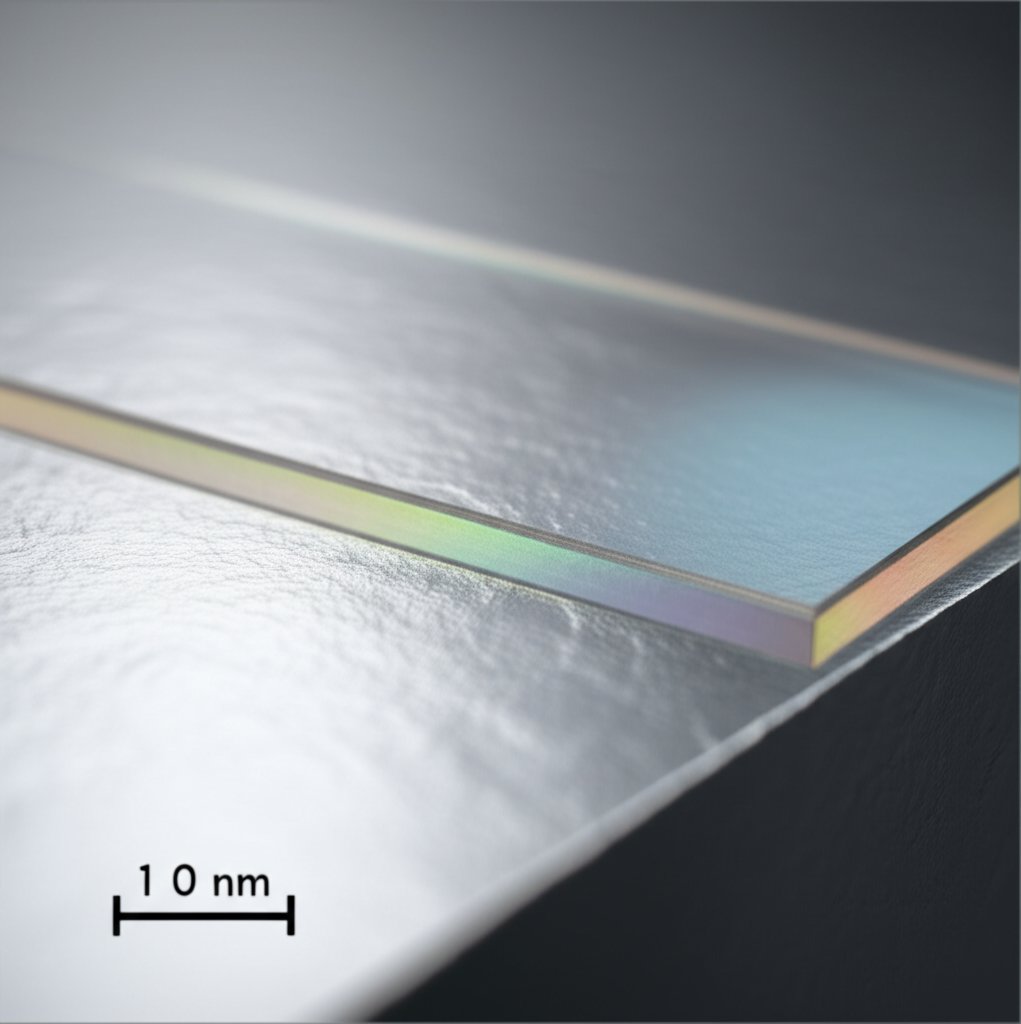

Unlike pure aluminum, which melts at a sharp 660.3°C (1220.5°F), alloys don’t melt at a single temperature. Instead, they have a melting range. This means the alloy starts to soften at one temperature (the solidus) and is fully liquid at a higher temperature (the liquidus). Between these points, the metal exists in a “mushy” or partially molten state, which is critical for processes like casting and welding.

| Term | Definition |

|---|---|

| Solidus | The highest temperature at which the alloy is completely solid |

| Liquidus | The lowest temperature at which the alloy is fully liquid |

| Melting Range | The temperature interval between solidus and liquidus |

Each element added to aluminum brings its own influence. Here’s a quick guide to the most common alloying elements and what they do:

Imagine you’re designing a part for an aircraft. You might choose a silicon-rich alloy for casting complex shapes, or a magnesium-copper blend for maximum strength. The specific aluminum alloy melting point and range will dictate the processing temperatures, safety margins, and even the tools you use.

Why not just use pure aluminum everywhere? Because the melting range of alloys provides flexibility—and sometimes essential safety. For example:

When your project demands reliability—be it in rail transit, solar frames, or advanced machinery—the precision of the alloy’s composition becomes non-negotiable. Even small impurities or incorrect ratios can shift the melting range, weakening the final product or causing unexpected failures. That’s why manufacturers and engineers turn to trusted suppliers like Shengxin Aluminum for:

"The composition of an aluminum alloy directly impacts its melting behavior. Elements such as magnesium and zinc form solid solutions with aluminum, which can either elevate or depress the melting point depending on their concentrations."

In summary, understanding the aluminum melting range is key to unlocking the full potential of this versatile metal. Whether you’re casting, welding, or designing for extreme environments, the right alloy—and a reliable supplier—makes all the difference. Next, we’ll zoom in on one of the most popular alloys, 6061 aluminum, and see how its specific chemistry shapes its melting behavior and practical uses. And this is a blog for your checking.

Ever wondered why 6061 aluminum is everywhere—from bike frames to aircraft fittings? The answer lies not just in its strength, but also in its well-defined melting range. If you’re curious about the 6061 aluminum melting point or how its chemistry shapes its behavior in high-heat applications, let’s break it down in simple terms.

Unlike pure aluminum, which melts at a single, sharp temperature, 6061 aluminum has a melting range. According to industry data, this range lies between 582°C and 652°C (1080°F to 1205°F) (source). What does this mean in practice? Imagine heating a block of 6061 alloy: it will begin to soften at the lower end (solidus, 582°C) and become fully liquid by the upper end (liquidus, 652°C). This gradual transition is crucial for manufacturing, casting, and welding processes, where precise temperature control is key to success.

| Property | Value |

|---|---|

| Solidus (Start of Melting) | 582°C / 1080°F |

| Liquidus (Fully Melted) | 652°C / 1205°F |

So, what gives 6061 its unique melting characteristics? The answer is in its composition. 6061 aluminum is primarily made up of aluminum (about 97.9%), but it’s the addition of magnesium (1.0%) and silicon (0.6%)—along with small amounts of copper and chromium—that sets it apart. Here’s how these elements affect its melting behavior:

These alloying elements create a balance between workability and durability, which is why 6061 is so popular in structural and engineering applications.

When you see “6061-T6,” you might wonder about the 6061 T6 melting temperature. The “T6” designation refers to a specific heat treatment process (solution heat-treated and artificially aged) that boosts mechanical strength and hardness. However, this tempering does not change the fundamental melting range of the alloy. Whether you’re working with 6061-O (annealed), 6061-T6, or another temper, the solidus and liquidus temperatures remain the same.

In summary, understanding the 6061 aluminum melting point is essential for anyone planning to cast, weld, or thermally process this alloy. Its predictable melting behavior, thanks to magnesium and silicon, makes it a go-to choice for countless applications. Up next, we’ll see how the story changes dramatically when aluminum reacts with oxygen to form aluminum oxide—a compound with a much higher melting point and major implications for industry.

Ever noticed how aluminum parts stay shiny for a while, but then develop a thin, almost invisible layer? That’s aluminum oxide (Al₂O₃) at work—a natural, protective shield that forms instantly when aluminum meets air. But here’s a surprising fact: while aluminum itself melts at about 660°C (1220°F), aluminum oxide has a melting point of 2,072°C (3,762°F). Why is there such a dramatic difference? Let’s break it down.

Imagine aluminum as a soft, workable metal. The moment it’s exposed to oxygen, it forms a super-thin, nearly transparent layer of aluminum oxide. This layer is so tough and stable that it protects the metal beneath from further corrosion—a key reason aluminum doesn’t rust like iron.

The secret lies in their atomic structure. Aluminum oxide’s “ionic giant lattice” bonds aluminum and oxygen atoms together in a dense, stable crystal. This structure requires much more energy (heat) to break apart compared to the metallic bonds in pure aluminum. That’s why the aluminum oxide melting point is over three times higher than that of aluminum metal.

| Material | Melting Point (°C) | Structure/Properties |

|---|---|---|

| Aluminum (Al) | 660 | Metallic, soft, ductile |

| Aluminum Oxide (Al₂O₃) | 2,072 | Crystalline, extremely hard, chemically inert |

So, when comparing aluminum oxide vs aluminum melting, you’re looking at two sides of the same coin: a versatile metal and its ultra-tough, heat-resistant shield. Understanding this relationship is crucial for anyone working with aluminum—especially in processes where heat and surface quality matter. Up next, we’ll explore how hobbyists and professionals can safely melt and cast aluminum, turning knowledge into practical results.

Ever thought about transforming scrap aluminum into custom parts, art, or tools in your own backyard? Melting aluminum at home opens up a world of creative possibilities, but it also comes with real challenges—especially when it comes to safety. Whether you’re a first-time hobbyist or a seasoned DIY metalworker, understanding the process, equipment, and crucial safety steps is key to a rewarding (and risk-free) experience.

Sounds complex? Actually, with the right setup, melting aluminum at home is achievable for most dedicated hobbyists. Here’s what you’ll need to get started:

Before you fire up your furnace, safety must come first. Molten aluminum is extremely hot and can cause severe injuries if mishandled. Here’s a practical checklist to keep you and your workspace safe:

| Safety Measure | Details |

|---|---|

| Personal Protective Equipment (PPE) | Wear heat-resistant gloves, long sleeves, goggles, and a face shield to protect against burns and splashes. |

| Ventilation | Work outdoors or in a well-ventilated area to avoid inhaling metal fumes and combustion byproducts. |

| Moisture Control | Keep all tools, molds, and scrap metal completely dry. Even a small amount of moisture can cause dangerous steam explosions when it contacts molten aluminum. |

| Workspace Cleanliness | Clear the area of flammable materials and clutter to reduce fire risk. |

| Proper Handling | Use appropriate tools and stable surfaces to move crucibles and pour metal safely. |

| Emergency Preparedness | Have a fire extinguisher and first aid kit on hand. Know how to respond to burns or spills. |

Remember, the aluminum casting safety practices you follow aren’t just for your protection—they also improve the quality of your finished pieces by reducing defects like porosity or cracks.

While home casting is a great way to experiment and learn, certain projects require a level of precision, strength, and consistency that’s tough to match in a garage setup. If your application demands complex shapes, tight tolerances, or industrial-grade performance—think structural components, custom frames, or architectural profiles—consider working with a professional supplier. Manufacturers like Shengxin Aluminum offer expertly engineered aluminum profiles, ensuring every piece meets strict quality standards for safety, durability, and reliability.

In short, melting aluminum at home can be safe and satisfying with the right knowledge and precautions. But when your ambitions grow, partnering with a trusted supplier brings your ideas to life with professional-grade results. Next, we’ll wrap up with a summary of key takeaways and how understanding melting points empowers smarter material choices in every project.

When you look back at the journey through aluminum’s melting behaviors, it’s clear this single property shapes everything from kitchen convenience to cutting-edge engineering. But what should you remember most about the aluminum melting point and its practical impact?

Imagine the difference between a thin sheet of foil, an everyday beverage can, and a massive structural beam. Each serves a distinct purpose, and each relies on a specific aluminum composition tailored to its environment:

What makes aluminum such a game-changer is its versatility. By controlling the melting point through alloying and advanced processing, manufacturers can create custom profiles and components for almost any challenge—whether it’s lightweight frames for solar panels or robust beams for high-speed trains. This adaptability is why aluminum is trusted in everything from aerospace to everyday appliances.

When your project demands more than basic metal—when you need consistent quality, tight tolerances, and proven reliability—working with a specialized supplier is essential. Companies like Shengxin Aluminum offer expertly engineered industrial aluminum profiles tailored to your exact needs. Their advanced alloy formulations, rigorous quality controls, and deep industry experience ensure your materials perform exactly as intended, every time.

"The right aluminum alloy, matched to your application and processed with precision, delivers unmatched performance—whether you’re building a skyscraper or a smartphone."

In summary, understanding the nuances of the aluminum melting point empowers smarter choices, safer projects, and more innovative solutions. Whether you’re casting at home or engineering the next big breakthrough, remember: the right knowledge—and the right supplier—make all the difference.

Aluminum melts at 660.32°C (1220.58°F), but its unique atomic structure and rapid formation of a tough oxide layer make it resistant to melting under normal conditions. The oxide layer, which forms instantly in air, has a much higher melting point, often requiring special preparation in welding and casting processes to achieve a clean melt.

Aluminum melts much faster than steel due to its lower melting point (660°C) compared to carbon steel, which typically melts above 1370°C. This means aluminum transitions to liquid at much lower temperatures, making it more suitable for applications where lower heat processing is beneficial.

Yes, aluminum foil melts at the same temperature as bulk aluminum—around 660°C. However, foil's thinness causes it to heat and cool quickly, and in direct flame, it may oxidize or disintegrate before forming a molten pool, making its behavior seem different from thicker aluminum pieces.

Alloying elements like magnesium, silicon, copper, and manganese modify aluminum's melting range. These additions can lower the melting point and create a melting range rather than a single temperature, enabling engineers to customize alloys for specific manufacturing and performance needs.

Safety is crucial when melting aluminum. Always use heat-resistant gloves, goggles, and a face shield. Work in a well-ventilated area, keep all tools and materials dry to prevent steam explosions, and have a fire extinguisher ready. Proper handling and workspace cleanliness further reduce risks during DIY aluminum casting.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360