T Slot Aluminium Extrusion is a versatile and robust construction material that has revolutionized the way industries approach structural design and assembly. Known for its distinctive 'T' shape, this type of extrusion is engineered to provide flexibility and strength, making it a preferred choice across various sectors. The basic design of T Slot Aluminium Extrusion involves a profile with a T-shaped groove that runs along its length, allowing for easy attachment of other components using specialized connectors and fasteners.

At its core, the T Slot design offers significant advantages in terms of adaptability and modularity. This unique feature enables users to create complex structures without the need for welding or additional machining, thus reducing both time and costs associated with assembly. The extrusions can be cut to any length and configured in numerous ways, providing endless possibilities for customization. This makes T Slot Aluminium Extrusion particularly popular in industries such as manufacturing, automation, and even DIY projects, where bespoke solutions are often required.

One of the primary reasons for the widespread adoption of T Slot Aluminium Extrusion is its ease of use. The system's modular nature allows for rapid prototyping and modifications, which is invaluable in dynamic work environments where changes are frequent. Furthermore, the extrusions are made from high-grade aluminum, which offers a favorable strength-to-weight ratio, ensuring that structures are not only durable but also lightweight. This characteristic is crucial in applications where mobility and ease of handling are important, such as in the construction of portable workstations or mobile machinery.

Additionally, T Slot Aluminium Extrusion is celebrated for its aesthetic appeal. The sleek, modern look of aluminum profiles can enhance the visual presentation of both industrial and consumer-facing products. This aspect, combined with its functional benefits, makes T Slot Aluminium Extrusion an ideal choice for projects that demand both form and function.

In summary, the fundamentals of T Slot Aluminium Extrusion lie in its innovative design and versatile application potential. Its unique T-shaped profile facilitates a wide range of uses, proving indispensable in industries that value efficiency, adaptability, and aesthetic appeal. As you consider materials for your next project, the adaptability and ease of T Slot Aluminium Extrusion stand out as compelling reasons to explore its capabilities further.

T Slot Aluminium Extrusion is celebrated for its adaptability and is utilized across a wide array of industries due to its modular design and ease of assembly. Its applications span from industrial machinery to custom displays, providing a reliable solution for creating robust and versatile structures. This section delves into the primary applications of T Slot Aluminium Extrusion, highlighting its role in modern engineering and design.

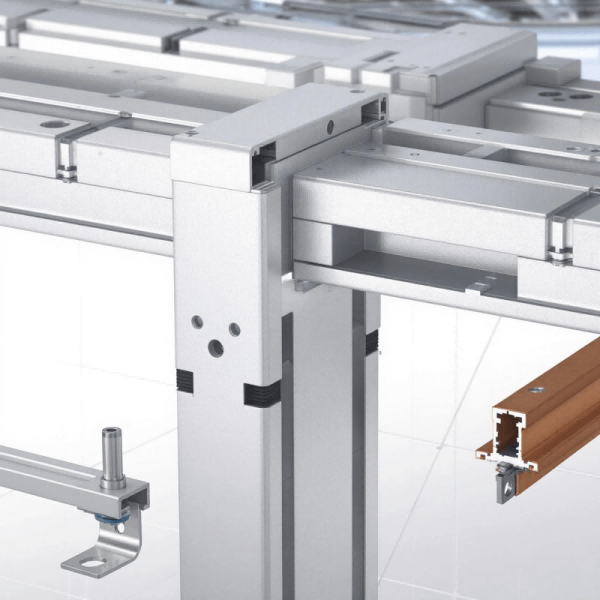

In the realm of industrial machinery, T Slot Aluminium Extrusion is indispensable. Its use in constructing frames for automation systems, conveyor belts, and machine guards underscores its robustness and flexibility. The modular nature of these extrusions allows engineers to design and assemble machinery components without the need for welding or complex fabrication processes. This not only reduces production time but also enhances the safety and efficiency of the machinery, as components can be easily adjusted or replaced as needed.

Another significant application of T Slot Aluminium Extrusion is in the creation of workstations and custom displays. The ability to configure these extrusions into various shapes and sizes makes them ideal for building ergonomic workstations tailored to specific tasks. In retail environments, custom displays crafted from T Slot Aluminium offer both durability and aesthetic appeal, allowing for the creation of visually striking setups that can be easily reconfigured to accommodate new products or layouts.

The versatility of T Slot Aluminium Extrusion extends to the construction of frames and enclosures. Whether used in the automotive industry for constructing lightweight yet strong vehicle components or in aerospace applications where weight and strength are critical, T Slot Aluminium provides a reliable solution. Its excellent strength-to-weight ratio and resistance to corrosion make it suitable for both indoor and outdoor applications, ensuring longevity and performance under various environmental conditions.

Furthermore, the ease with which these extrusions can be customized means they are not limited to standard profiles. They can be tailored to meet specific project requirements, providing a unique advantage over traditional materials. This customization capability is particularly beneficial in industries where precision and specific design features are paramount.

In conclusion, the applications of T Slot Aluminium Extrusion are vast and varied, reflecting its adaptability and efficiency in numerous sectors. Its role in industrial settings, as well as in consumer-facing environments, highlights its importance as a material of choice for modern construction and design. As you explore potential materials for your projects, consider the benefits of T Slot Aluminium Extrusion for its ability to deliver both functional and aesthetic solutions.

T Slot Aluminium Extrusion offers a multitude of advantages that make it a superior choice over traditional materials like steel or wood. Its unique properties cater to a wide range of applications, ensuring efficiency and cost-effectiveness in various industrial and commercial settings. Here, we delve into the key benefits that underscore the popularity of T Slot Aluminium Extrusion.

One of the primary benefits of T Slot Aluminium is its lightweight nature. Aluminum is significantly lighter than steel, which not only reduces handling and transportation costs but also simplifies the assembly process. Despite its lightness, aluminum offers a high strength-to-weight ratio, making it ideal for structures that require both durability and ease of movement. This characteristic is particularly beneficial in industries such as aerospace and automotive, where weight reduction is crucial.

Aluminium extrusion advantages extend to its durability and natural resistance to corrosion. Unlike steel, which can rust over time, aluminum forms a protective oxide layer that shields it from environmental factors, ensuring longevity and minimal maintenance. This makes T Slot Aluminium Extrusion an excellent choice for outdoor applications or environments exposed to moisture and other corrosive elements.

From a financial perspective, T Slot Aluminium is cost-effective not only because of its lower material and shipping costs but also due to its ease of manipulation. Aluminum's malleability allows it to be easily cut, drilled, and shaped, reducing labor costs and time in the manufacturing process. The modular design of T Slot systems further enhances their flexibility, allowing for quick modifications and reconfigurations without the need for specialized tools or expertise.

The ease of assembly is another standout feature of T Slot Aluminium Extrusion. Its design facilitates rapid construction and dismantling, making it ideal for projects that require frequent adjustments or relocations. This adaptability is invaluable in dynamic work environments, such as manufacturing floors or trade shows, where setups may need to change swiftly to meet evolving demands.

In summary, the advantages of using T Slot Aluminium Extrusion are numerous, encompassing lightweight strength, durability, cost savings, and unparalleled versatility. These attributes make it a preferred material for engineers and designers looking to optimize their projects' efficiency and performance. As you consider materials for your next venture, the benefits of T Slot Aluminium Extrusion present compelling reasons to explore its potential.

When approaching a project with T Slot Aluminium Extrusion, several design considerations are crucial to ensure structural integrity and project success. Understanding these factors can help optimize the use of this versatile material, making it an ideal choice for a wide range of applications.

A primary consideration in designing with Industrial T Slot Aluminium Extrusion is assessing the load capacity. The area moment of inertia plays a significant role in determining the rigidity of the extrusion. Designers should evaluate the maximum bending stress and deflection to ensure that the extrusion can support the intended loads without failure. Calculating the maximum allowable buckling load using Euler's critical load formula is also essential, especially for vertical applications where gravitational forces are prominent.

Environmental considerations are pivotal when selecting T Slot Aluminium Extrusion. Aluminum's natural corrosion resistance is advantageous in outdoor or moist environments, reducing maintenance needs and extending the lifespan of the structure. However, designers must also account for temperature fluctuations, as extreme temperatures can affect the material's expansion and contraction, potentially impacting joint stability.

Another key aspect is the compatibility of T Slot Aluminium Extrusion with other materials. The extrusion's modular nature allows for integration with various components, but ensuring that these materials have compatible thermal expansion rates and load-bearing capacities is crucial. Using appropriate connectors and fasteners can enhance joint strength and prevent movement under load.

The configuration of assembly joints significantly affects the structural integrity of T Slot Aluminium Extrusion projects. Avoiding reliance on friction-based joints and opting for reaction force-based configurations can enhance strength. When friction-only joints are necessary, calculating the required number of fasteners to support the load can prevent joint failure and optimize costs.

In conclusion, by considering load capacity, environmental factors, material compatibility, and joint configurations, designers can maximize the potential of T Slot Aluminium Extrusion in their projects. These considerations not only ensure safety and durability but also enable the creation of efficient and adaptable structures. As you plan your next project, leveraging these design tips will help you harness the full capabilities of T Slot Aluminium Extrusion.

Assembling and installing T Slot Aluminium Extrusion systems can be both straightforward and rewarding, provided you follow some essential guidelines. These tips will help ensure that your assembly process is efficient and the resulting structure is robust and reliable.

Before starting your assembly, gather the necessary tools. Essential tools include Allen wrenches, a hex key set, and a torque wrench. These tools are crucial for tightening the fasteners that hold the extrusion profiles together. Depending on your specific project, you may also need cutting tools for resizing profiles and a drill for creating additional holes for custom fittings. Using the correct tools not only speeds up the assembly process but also ensures that the connections are secure and precise.

Before you begin assembling, it’s important to organize all components and hardware. Unpack and sort all profiles, nuts, bolts, and brackets. This step is crucial to avoid confusion and ensure that you have all necessary parts before starting the assembly. Many manufacturers provide pre-assembled kits, which can save time and reduce the risk of missing components. If your kit includes diagrams, use them to verify that each component is accounted for, as suggested by Angle Lock.

Aligning the components accurately is critical for maintaining the structural integrity of your assembly. Begin by loosely connecting the profiles using T-nuts and fasteners. This allows for adjustments to ensure everything is square and level before final tightening. Use a level and a square to verify the alignment of the assembly. For larger structures, it might be beneficial to have an extra pair of hands to assist with holding components in place while you tighten the connections.

Once aligned, tighten the fasteners incrementally, moving around the structure to ensure even pressure distribution. This method helps prevent warping and ensures that the assembly maintains its shape over time. For added stability, consider using corner brackets and gussets, which enhance rigidity and support.

To ensure the long-term stability and performance of your T Slot Aluminium Extrusion structure, regularly check and maintain the connections. Periodically retighten fasteners and inspect the assembly for any signs of wear or misalignment. In environments subject to vibration or temperature changes, these checks are particularly important.

In conclusion, assembling T Slot Aluminium Extrusion systems requires careful planning and attention to detail. By choosing the right tools, organizing your components, and aligning your assembly accurately, you can create robust and adaptable structures. These practical tips not only enhance the efficiency of your assembly process but also ensure the longevity and reliability of your projects. As you gain experience, you'll find that working with T Slot Aluminium Extrusion becomes an intuitive and rewarding process, opening up endless possibilities for customization and design.

When choosing between T Slot and V Slot Aluminium Extrusions, understanding their distinct features and applications is crucial. Both types of extrusions offer unique advantages, making them suitable for different projects and industries. Let's delve into the key differences and potential applications to help you make an informed decision.

The primary distinction between T Slot and V Slot Aluminium Extrusions lies in their cross-sectional design. T Slot extrusions feature a T-shaped groove that runs along the length of the profile, making them highly adaptable for various attachments and configurations. This design is particularly beneficial for projects requiring a high degree of modularity and precision, such as industrial machinery and robotics. The T-slot allows for easy installation and reconfiguration of components, providing flexibility in design and assembly.

In contrast, V Slot extrusions have a V-shaped groove, which is specifically designed to accommodate V-slot wheels. This feature is ideal for creating linear motion systems, such as those used in 3D printers and CNC machines. The V-slot provides a smooth and stable track for wheels, enabling precise movement and positioning. This makes V Slot extrusions the preferred choice for applications that demand accurate linear motion and stability.

T Slot Aluminium Extrusions are renowned for their versatility and are used in a wide range of applications. They are ideal for constructing frames, enclosures, and workstations, where the ability to customize and modify structures is essential. The ease of assembly and reconfiguration makes T Slot extrusions a popular choice in dynamic environments where design changes are frequent, such as manufacturing and automation industries.

On the other hand, V Slot Aluminium Extrusions excel in applications that require precise linear motion and positioning. They are commonly used in the construction of 3D printers, CNC machines, and other equipment where smooth and accurate movement is critical. The V-slot design offers a stable and reliable platform for linear motion components, enhancing the performance and efficiency of these systems.

The decision between T Slot and V Slot Aluminium Extrusions ultimately depends on the specific needs of your project. If your application requires a high degree of modularity and flexibility, T Slot extrusions are the ideal choice. They provide the versatility needed to build a wide range of structures and systems, making them suitable for diverse industrial and commercial applications.

Conversely, if your project involves creating systems with precise linear motion, V Slot extrusions offer the best solution. Their design caters to applications that demand accuracy and stability, ensuring optimal performance in motion-oriented projects.

In conclusion, both T Slot and V Slot Aluminium Extrusions have unique features and advantages that cater to different project requirements. By understanding the differences in design and application, you can select the most suitable extrusion to achieve your desired results. As you explore these options, consider partnering with professional aluminum profile customization manufacturers to leverage their expertise in selecting and utilizing the right extrusion for your needs.

Selecting a reliable supplier for T Slot Aluminium Extrusion is crucial to ensuring the success of your projects. The right supplier will not only provide high-quality materials but also offer the necessary support and customization options to meet your specific needs. Here, we explore key factors to consider when choosing a supplier and introduce Anhui Shengxin New Materials Co., Ltd. as a leading manufacturer in the industry.

The first step in choosing a T Slot supplier is assessing the quality of their products. Look for suppliers who adhere to international standards and have a proven track record of delivering durable and reliable aluminium extrusions. High-quality extrusions should exhibit excellent strength, precision, and finish, ensuring they can withstand the demands of your application. It's also beneficial to request samples to evaluate the product quality firsthand before making a commitment.

Customization is a significant advantage of using T Slot Aluminium Extrusions, and your supplier should offer a range of options to tailor the profiles to your project's specifications. Whether you require specific dimensions, surface finishes, or additional processing, a supplier with robust customization capabilities can significantly enhance the functionality and aesthetics of your structures. Consider suppliers who can provide both standard and bespoke solutions to cater to your unique requirements.

Excellent customer service is a hallmark of the best aluminium extrusion manufacturers. A responsive and knowledgeable supplier can make a substantial difference in the success of your project. Look for suppliers who offer comprehensive support throughout the purchasing and assembly process, including technical assistance and after-sales service. This ensures that any issues are promptly addressed, and you receive the guidance needed to optimize the use of T Slot Aluminium Extrusions.

Anhui Shengxin New Materials Co., Ltd. stands out as a premier choice for those seeking a reliable T Slot supplier. As the largest aluminium profiles manufacturer in Anhui Province, Shengxin boasts over 100 production lines and a remarkable annual production capacity of 100,000 tons. Their extensive capabilities encompass a wide range of processes, including extrusion, anodizing, and powder coating, ensuring high-quality and versatile aluminium profiles.

Shengxin's commitment to quality and innovation is evident in their collaborations with esteemed institutions like Hefei Industrial University, enhancing their research and development efforts. Their products have been utilized in high-tech applications across various sectors, including rail transit and new energy vehicles, earning them a reputation for excellence and reliability.

For those looking to maximize the potential of T Slot Aluminium Extrusion, partnering with Shengxin offers a strategic advantage. Their expertise in customization, coupled with a strong emphasis on customer satisfaction, makes them an ideal partner for projects of any scale. Explore Shengxin's offerings at their official website to learn more about their capabilities and how they can support your next project.

T Slot Aluminium Extrusion stands out as a premier choice for a multitude of applications, thanks to its unique blend of versatility, strength, and ease of use. As explored throughout this guide, its modular design and adaptability make it an invaluable asset across industries ranging from manufacturing and automation to retail and DIY projects. The ability to easily customize and reconfigure these extrusions allows for innovation and efficiency, enabling users to tailor solutions to specific project needs.

One of the key advantages of T Slot Aluminium Extrusion is its ability to serve diverse functions. Whether constructing industrial workstations, protective enclosures, or dynamic retail displays, the possibilities are virtually limitless. This adaptability not only supports creative design but also facilitates rapid prototyping and adjustments, which are crucial in today’s fast-paced environments. By maximizing T Slot use, businesses can enhance productivity and streamline operations, ultimately leading to cost savings and improved project outcomes.

For those considering aluminium extrusion projects, the potential benefits are substantial. The lightweight yet durable nature of aluminum, combined with its resistance to corrosion, makes it an ideal material for both indoor and outdoor applications. Its aesthetic appeal further enhances its suitability for consumer-facing projects, where both form and function are paramount. As industries continue to evolve, the demand for flexible and efficient construction solutions will only increase, making T Slot Aluminium Extrusion a strategic choice for future projects.

To fully leverage the capabilities of T Slot Aluminium Extrusion, partnering with a reliable supplier is essential. Anhui Shengxin New Materials Co., Ltd. exemplifies the qualities of a trusted partner, offering high-quality products and comprehensive support. With their extensive production capabilities and commitment to innovation, Shengxin provides the expertise needed to bring complex projects to fruition. By collaborating with such manufacturers, businesses can ensure they receive the best materials and guidance to maximize their project's potential.

In conclusion, T Slot Aluminium Extrusion offers a powerful combination of flexibility, durability, and aesthetic appeal, making it a top choice for a wide array of applications. As you plan your next venture, consider the advantages of this versatile material and the benefits of working with industry leaders like Anhui Shengxin. Their dedication to quality and customer satisfaction can help you achieve exceptional results, ensuring your projects are not only successful but also set new standards in innovation and design. Explore the possibilities with T Slot Aluminium Extrusion and unlock new opportunities for your business.

T Slot Aluminium Extrusions are widely used in industrial machinery, automation systems, workstations, and custom displays due to their modular design and ease of assembly. They provide a reliable solution for constructing frames, enclosures, and other structural components.

T Slot Aluminium is favored for its lightweight yet strong nature, corrosion resistance, and cost-effectiveness. It offers easy assembly and reconfiguration, making it ideal for dynamic environments requiring frequent modifications.

T Slot extrusions have a T-shaped groove for modular attachments, ideal for flexible designs. V Slot extrusions feature a V-shaped groove for linear motion systems, perfect for applications needing precise movement like 3D printers.

Key considerations include load capacity, environmental factors, material compatibility, and joint configurations. These ensure structural integrity and optimal performance for various applications.

Select a supplier based on product quality, customization options, and customer service. Anhui Shengxin New Materials Co., Ltd. offers extensive capabilities and high-quality products, making them a leading choice in the industry.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360