Have you ever wondered why so many of the products you use daily—your smartphone, laptop, kitchen pans, or even the window frames in your home—seem to last longer and look better than ever? The secret often lies in a material called anodized aluminum. But what makes this metal so special, and why has it become a staple across modern industries?

Imagine a metal that's not only lightweight but also incredibly strong, resistant to corrosion, and available in a rainbow of colors. Sounds complex? In reality, anodized aluminum is the result of a unique process that transforms ordinary aluminum into a powerhouse material, prized for its enhanced durability and performance. You'll notice its presence in:

The secret to its popularity? The anodizing process creates a tough, integrated surface layer that doesn't peel, chip, or fade like paint or coatings. This makes anodized aluminum a go-to choice for products that demand both beauty and endurance.

Throughout this guide, we'll uncover the science behind anodized aluminum, explore its wide-ranging applications, discuss safety considerations, and provide practical sourcing tips. Whether you're an industry professional, designer, or curious homeowner, you'll gain valuable insights into why anodized aluminum is shaping the future of modern materials.

When you hear the term "anodized aluminum," you might picture a shiny, colored metal surface or wonder if it's just another type of coating. But what is anodized aluminum, really, and why does it stand apart from ordinary aluminum?

Unlike paint or plating, anodized aluminum is not covered by an external layer. Instead, it undergoes an electrochemical process—known as anodizing—that transforms the very surface of the metal itself. Here’s how it works in simple terms:

This means the protective layer won’t chip, peel, or flake off, even under tough conditions. The result? A surface that’s far more resilient than untreated aluminum.

Imagine two pieces of metal: one is plain, raw aluminum, and the other is aluminum anodized through this special process. Here’s what you’ll notice:

Because the anodized layer is porous at a microscopic level, it can also be dyed in a variety of colors or sealed for extra protection. This makes it a favorite for products that require both durability and design flexibility.

Curious about the step-by-step process that creates this remarkable material? Next, we’ll break down how aluminum undergoes the anodizing transformation, revealing the science behind its superior properties.

Ever wondered how to anodize aluminum and what really happens during the process? If you imagine a simple paint job, think again. The transformation of raw aluminum into anodized aluminum involves a fascinating blend of science and precision engineering, resulting in a material that’s tougher, more beautiful, and longer-lasting than ever before.

At the heart of anodizing aluminum is an electrochemical process called electrolysis. Unlike painting or plating, this process doesn’t just add a layer on top—it actually changes the structure of the aluminum’s surface. Here’s what happens:

This aluminum oxide layer is fully integrated with the base metal, making it extremely resistant to corrosion and wear. The result? A surface that’s much harder and more durable than untreated aluminum, with a unique ability to accept color and sealants.

The aluminum anodization process is methodical and involves several carefully controlled stages. Here’s a breakdown of the typical steps involved in how do you anodize aluminum:

Not all anodizing is the same. The process can be customized for different needs—whether you’re looking for decorative finishes or extreme durability. Here are the main types:

Every stage of aluminum alloy anodizing is critical to the final quality. For example, improper cleaning can leave residues that ruin the finish, while poor sealing can lead to fading or corrosion over time. That’s why both industrial manufacturers and DIY enthusiasts must follow the process closely for the best results.

Now that you know how to anodize aluminum and the science behind it, you’ll appreciate why anodized aluminum stands out for its toughness and beauty. Up next, we’ll dive into the remarkable benefits and unique properties that make this material a top choice for so many demanding applications.

Why do so many industries—from architecture to electronics—choose anodized aluminum material over untreated metal? If you’ve ever wondered what sets it apart, the answer lies in its unique blend of strength, durability, and design flexibility. Let’s break down the remarkable properties that make anodized aluminum a go-to choice for demanding applications.

Imagine dropping your phone or leaving your outdoor furniture exposed to rain and sun for years. With untreated aluminum, you’d likely see scratches, stains, or even rust. Anodized aluminum, however, is engineered to overcome these challenges. Here’s how:

For situations where extreme durability is a must—think industrial machinery, cookware, or aerospace parts—hard anodized aluminum steps up the game. This variant undergoes a more intense anodizing process, resulting in an even thicker and tougher oxide layer. The benefits?

Whether you’re choosing material for a commercial building façade or a nonstick frying pan, hard anodized aluminum offers a robust solution that stands up to years of use.

To clearly see the difference, take a look at this comparison table:

| Property | Untreated Aluminum | Anodized Aluminum |

|---|---|---|

| Surface Hardness | Soft, easily scratched | Much harder, highly resistant to abrasion |

| Corrosion Resistance | Moderate; prone to pitting and oxidation | Excellent; protective oxide layer prevents rust |

| Aesthetic Options | Limited, dull metallic appearance | Customizable colors, matte or glossy finishes |

| UV Stability | May discolor or chalk over time | Resists fading and chalking outdoors |

| Electrical Conductivity | Conductive | Non-conductive surface layer |

| Maintenance | Requires frequent cleaning; stains easily | Low maintenance; easy to clean |

As you can see, the transformation from untreated to anodized aluminum material is more than skin deep—it’s a fundamental upgrade in both performance and appearance.

Now that you know what makes anodized aluminum so valuable, let’s see how these properties translate into real-world performance—especially in the kitchen, where heat, durability, and easy cleaning are essential. Next, we’ll dive into the world of anodized aluminum cookware and why it’s favored by home cooks and chefs alike.

When you reach for a pan to scramble eggs or simmer a sauce, have you ever wondered why some cookware makes the process so much smoother? If you’ve used anodized aluminum cookware, you’ve likely noticed the difference—quick, even heating, easy cleanup, and impressive durability. But what gives these pans their edge, and how do they stack up against other materials?

Imagine a kitchen where your pans don’t warp, scratch, or require hours of scrubbing. That’s the everyday reality with anodized aluminum pans and saucepans. The secret lies in the anodizing process, which transforms ordinary aluminum into a material that’s harder, more resilient, and less reactive. Here’s what sets these kitchen staples apart:

The versatility of anodized aluminum means you’ll find it in a wide array of kitchen essentials. Here are some of the most popular types:

Looking for a real-world example? The Tramontina 3-pack hard anodized aluminum ceramic nonstick fry pan set demonstrates the practical benefits of this material. This set includes 8", 10", and 12" fry pans—each designed for different cooking needs, from single servings to family meals. Here’s what makes it stand out:

This set is a prime example of how modern hard anodized aluminum cookware blends professional-grade performance with user-friendly features.

Wondering how these pans measure up to other cookware materials? Here’s a quick comparison:

In summary, if you want cookware that combines fast, even heating, toughness, and easy cleaning, hard anodized aluminum cookware is a smart choice for any home chef. Next, let’s address a key concern for many cooks: Is anodized aluminum safe for food preparation and everyday use?

When you’re choosing new pots and pans for your kitchen, safety is often the first question that comes to mind. Is anodized aluminum safe? Can you trust hard anodized aluminum cookware for daily meals, or are there hidden risks? Let’s break down the facts and address the most common concerns so you can cook with confidence.

Imagine you’re preparing a tomato-based sauce or a citrus marinade—both highly acidic foods. With regular aluminum cookware, there’s a risk that the metal might react with your ingredients, potentially altering the taste and leading to small amounts of aluminum leaching into your food. But with anodized aluminum, the story is different. Here’s why:

Is hard anodized aluminum cookware safe? Absolutely. In fact, hard anodized cookware is engineered for even greater durability and safety. The thickened oxide layer is highly resistant to scratching, corrosion, and everyday wear and tear. Here’s what you should know:

You may have heard claims that aluminum cookware can cause health problems or even cancer. The reality? Extensive research and regulatory reviews have found no credible evidence linking anodized aluminum cookware to cancer or significant health risks when used appropriately. The anodic layer is stable, non-toxic, and does not break down under normal cooking conditions.

Key Takeaway: Unless your cookware is old, heavily scratched, or damaged, anodized and hard anodized aluminum pans are safe for everyday cooking—including with acidic foods. For best results, always follow manufacturer care instructions and avoid using metal utensils that could damage the surface.

With safety concerns addressed, you can focus on choosing cookware that fits your style and needs. In the next section, we’ll explore the versatility of anodized aluminum sheets, colors, and finishes for projects beyond the kitchen.

Ever walked past a sleek storefront, admired a high-end appliance, or noticed the crisp lines on a modern building facade? Chances are, you were looking at anodized aluminum sheet—a material prized for its blend of strength, style, and adaptability. But what makes these sheets so popular across industries, and how do their colors and finishes open up creative possibilities?

Imagine specifying a material for a new architectural project or designing components for cutting-edge electronics. You need something that’s not only durable but also visually striking. This is where anodized aluminum sheet metal shines. Here’s why:

From architectural panels and signage to appliance facings and electronic enclosures, the versatility of anodized aluminum sheets is unmatched.

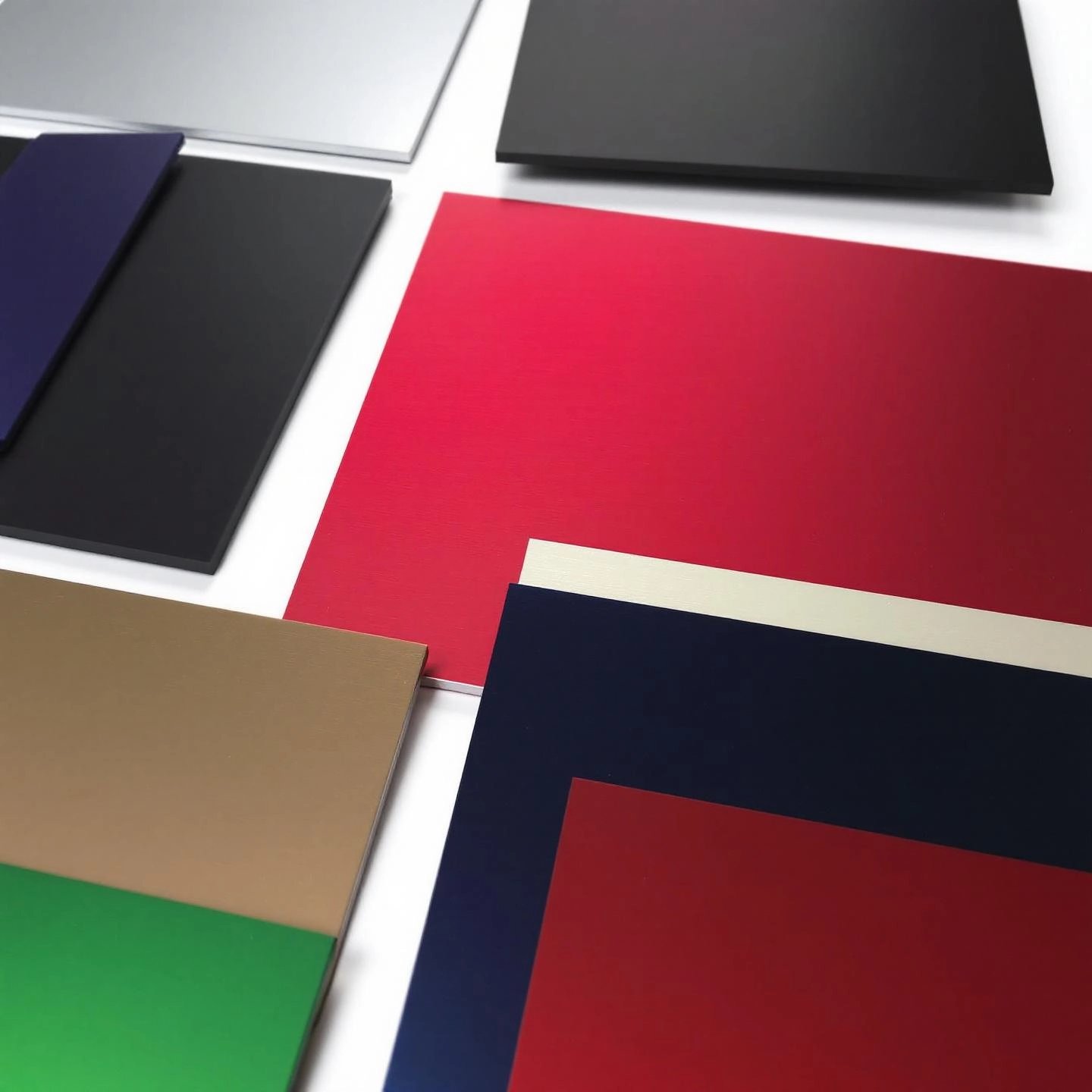

One of the standout features of anodized aluminum is its ability to take on a wide spectrum of colors and finishes. Whether you want a subtle metallic sheen or a dramatic matte black, there’s an option for every design vision. But how are these anodized aluminum colors achieved?

After coloring, a sealing step locks in the shade and boosts durability, ensuring the finish stays vibrant and protected against weather and wear.

Beyond color, the finish of anodized aluminum sheet metal can be fine-tuned for different visual and tactile effects. Here are some of the most common options:

When sourcing anodized aluminum sheets for your project, consider:

For custom orders—such as unique colors, patterns, or sizes—clear communication with your supplier is key to achieving the desired result.

Not all anodized aluminum is created equal. The quality of the finish, color consistency, and durability depend on advanced process control and experienced manufacturing. Leading companies like Shengxin Aluminum invest in state-of-the-art technology and rigorous quality checks to deliver high-quality, customizable solutions for architectural, industrial, and specialty applications.

Whether you’re designing a modern facade, specifying components for electronics, or seeking a durable, stylish finish for consumer products, anodized aluminum sheet metal offers the flexibility and performance to bring your ideas to life. Next, we’ll explore how DIY enthusiasts can experiment with anodizing at home, turning ordinary aluminum into custom, high-performance pieces.

Ever wondered if you could give your own aluminum parts a professional, durable finish—right in your garage? How to anodize aluminum at home might sound intimidating, but with the right approach, it’s an achievable project for DIY enthusiasts. Let’s break down the essentials, from understanding the process to gathering equipment and staying safe.

Think of anodizing as a controlled way to create a tough, protective oxide layer on the surface of aluminum. Instead of applying a coating, you use an electrochemical process to transform the outermost layer of the metal itself. This not only improves corrosion resistance and wear but also lets you add vibrant colors if desired.

While you can buy a complete aluminum anodizing kit, many DIYers assemble their own setup. Here’s a practical checklist of what’s required:

Most of these items are available at hardware stores or online. If you’re planning frequent projects, investing in a ready-made aluminum anodizing kit can save time and ensure you have all the right components.

Each step requires patience and attention to detail—results improve with practice. Don’t be discouraged if your first attempt isn’t perfect; even seasoned DIYers tweak their process over time.

Anodizing at home involves strong acids and electricity. Always follow strict safety protocols:

While home anodizing is rewarding and offers creative freedom, it’s important to be realistic. Professional shops use advanced controls for temperature, voltage, and cleanliness, resulting in flawless, repeatable finishes—especially for large or mission-critical parts. At home, you may see some color variation or minor imperfections, but with care, you can achieve impressive results for small projects, custom parts, or hobby use.

Ready to try your hand at anodizing aluminum? With the right tools, safety measures, and a bit of experimentation, you can transform everyday aluminum into durable, eye-catching pieces. Next, we’ll help you find professional anodizing services and quality materials if your project calls for a commercial-grade finish.

So, you’ve learned how to anodize aluminum at home—but what if your project demands a flawless, large-scale, or highly specialized finish? Or maybe you need to source specific parts, like an aluminum anode rod for your water heater, and want to make the best choice for your needs. Let’s explore how to find top-notch aluminum anodizing services, source quality materials, and make smart decisions for everything from architectural panels to water heater maintenance.

Searching for aluminum anodizing near me or anodizing aluminum near me can feel overwhelming, especially with so many options available. Here’s a simple checklist to help you identify reputable providers and ensure your parts get the professional treatment they deserve:

For specialized architectural or industrial needs, consider large-scale manufacturers with advanced technology and deep processing capabilities. Companies like Shengxin Aluminum stand out for their comprehensive range, from extrusion to anodizing and custom fabrication, making them ideal for bulk orders or projects demanding strict quality standards.

When your project calls for raw materials—like anodized aluminum sheets, profiles, or custom parts—it pays to choose suppliers who can guarantee consistency and performance. Here are a few tips:

This approach is especially important for projects where visual consistency, durability, and precise dimensions are non-negotiable—think building facades, transportation components, or branded products.

Need an aluminum anode rod or aluminum zinc anode rod for your water heater? The choice between aluminum and magnesium rods can impact both performance and water quality. Here’s a quick comparison:

| Feature | Aluminum Anode Rod | Magnesium Anode Rod |

|---|---|---|

| Best For | Hard water, older heaters, well water systems | Soft water, newer heaters, RVs |

| Lifespan | Longer due to slower depletion | Shorter, more frequent replacement |

| Water Quality | Can cause metallic taste, sulfur smell | Improves taste, reduces odor |

| Corrosion Protection | Good, especially in hard water | Superior, more reactive |

For homes with hard water or older tanks, aluminum rods are often recommended due to their durability and resistance to mineral buildup. Magnesium rods, on the other hand, provide better corrosion protection and can enhance water quality, making them ideal for soft water or newer systems. If you’re experiencing frequent rod depletion or persistent water quality issues, a powered anode rod may be worth considering for long-term, low-maintenance protection.

For large-scale, specialized, or mission-critical projects, partnering with a reputable manufacturer ensures you receive materials and finishes that meet the highest industry standards. Shengxin Aluminum, for example, offers a full spectrum of anodizing, fabrication, and quality control services tailored to demanding applications in architecture, transportation, and industry.

Whether you’re restoring a water heater, designing a building facade, or sourcing components for an industrial system, the right supplier makes all the difference. In the final section, we’ll recap the key advantages of anodized aluminum and offer guidance for choosing the best materials for your next project.

When you look around—whether at the devices in your hand, the buildings you pass, or the cookware in your kitchen—chances are, anodized aluminum plays a part in your everyday life. But what truly sets this material apart?

Imagine a material that combines lightweight strength with exceptional durability. Anodized aluminum delivers just that, thanks to its unique electrochemical transformation:

From aerospace to architecture, electronics to kitchenware, the applications for anodized aluminum continue to grow. Its combination of form and function allows it to meet the demands of:

As industries evolve and sustainability becomes ever more important, anodized aluminum’s recyclability and minimal environmental impact further cement its place as a material of the future.

Ready to incorporate anodized aluminum into your next project? The quality of your results depends on the expertise and technology behind the material. Working with reputable manufacturers—such as Shengxin Aluminum—ensures you receive consistent finishes, precise customization, and reliable support for projects of any scale. Their advanced processes and commitment to quality help bring your ideas to life, whether you’re building, designing, or cooking.

In summary: Anodized aluminum isn’t just a trend—it’s a proven, adaptable, and sustainable solution powering innovation across the globe. For your next design, industrial, or kitchen project, consider the lasting value and versatility that this remarkable material brings.

Yes, anodized aluminum is considered safe for daily use in cookware and other applications. The anodizing process creates a stable, non-reactive oxide layer that prevents aluminum from leaching into food or the environment. This protective surface is durable, non-toxic, and does not break down under normal conditions, making it suitable for both kitchenware and industrial products.

Anodized aluminum is aluminum that has undergone an electrochemical process to thicken its natural oxide layer. Unlike regular aluminum, which has a thin, easily scratched surface, anodized aluminum features an integrated, durable layer that resists corrosion, wear, and fading. This process also allows for a variety of color and finish options, making it more versatile and longer-lasting than untreated aluminum.

Anodized aluminum cookware is safe for cooking because the anodized layer acts as a barrier, preventing the metal from reacting with acidic foods. This means you can cook tomato-based or citrus dishes without worrying about metallic tastes or health risks. For best results, avoid using abrasive cleaners or metal utensils to preserve the integrity of the anodized surface.

The main benefits of anodized aluminum include enhanced hardness, superior corrosion and abrasion resistance, a wide range of colors and finishes, UV stability, and low maintenance. It is also lightweight, non-conductive at the surface, and environmentally friendly due to its recyclability and non-toxic nature.

To find professional anodizing services, search for providers with experience in your required finish and application. Look for companies offering customization, quality control, and positive client reviews. For sourcing materials or large-scale projects, working with established manufacturers like Shengxin Aluminum ensures access to high-quality, customizable anodized aluminum products for architectural, industrial, or consumer needs.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360