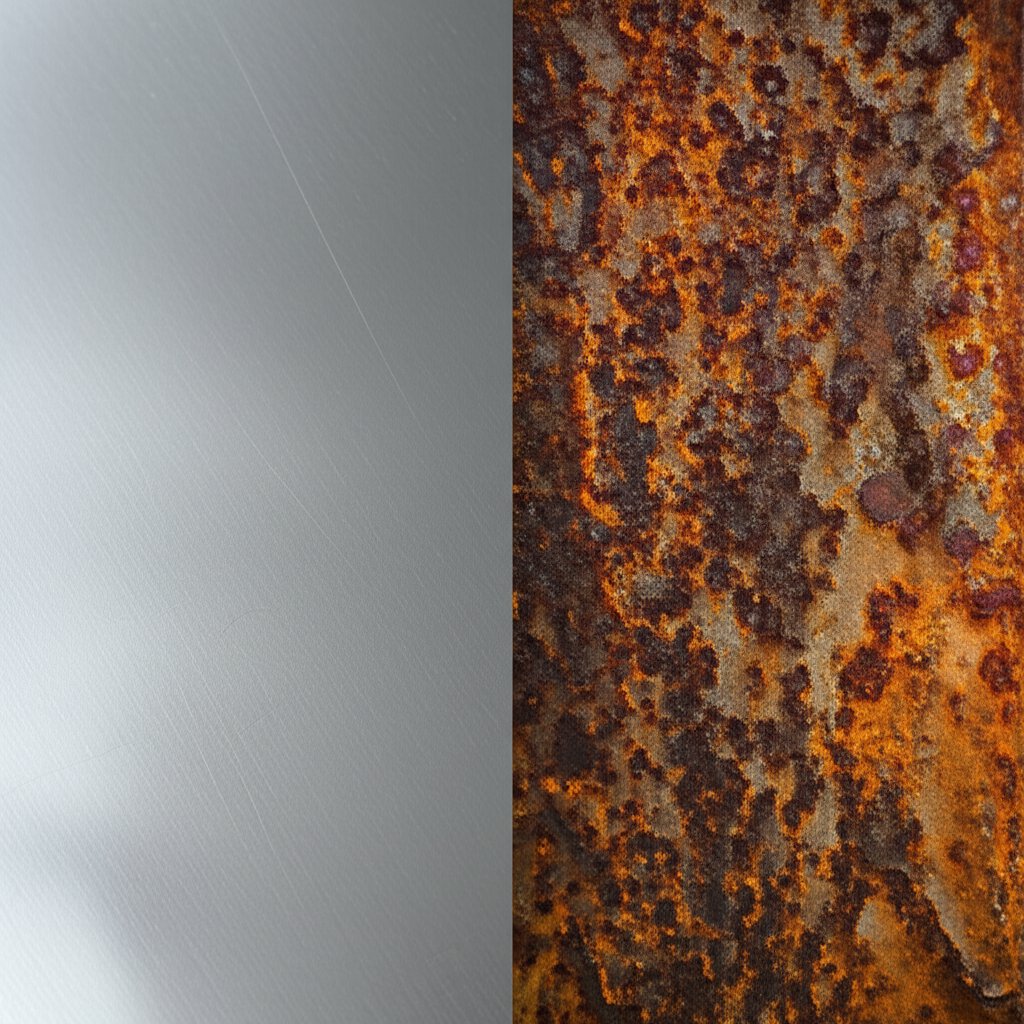

When you hear the phrase aluminum and rust, you might picture corroded metal or wonder if aluminum can rust just like iron. Sounds complex? The truth is, the relationship between these two materials is both fascinating and often misunderstood. While rust is a familiar sight on old bikes, fences, and cars, aluminum behaves quite differently when exposed to the elements.

Let’s start by clearing up a common misconception: aluminum does not rust. Rust is a specific term for the reddish-brown flakes that form when iron or steel reacts with oxygen and moisture—a process called oxidation. In contrast, aluminum undergoes a unique form of oxidation that doesn’t result in the flaky, damaging rust we see on iron. Instead, when aluminum meets oxygen, it forms a thin, hard layer of aluminum oxide. This layer is so effective at protecting the metal that it actually prevents further corrosion, making aluminum a top choice for everything from airplanes to outdoor furniture (source).

But the story of aluminum and rust doesn’t stop at simple corrosion. Did you know that when powdered aluminum is mixed with rust (iron oxide) under the right conditions, it can trigger one of the most dramatic chemical reactions in material science—the thermite reaction? This process generates extreme heat and molten iron, and has been used in everything from welding railroad tracks to science demonstrations. On the flip side, aluminum also plays a practical role in everyday rust removal, where a humble piece of aluminum foil can help restore chrome and iron surfaces to their former shine.

In this essential guide, you’ll discover the science behind these reactions, practical applications for rust removal, and the crucial differences in how aluminum and iron respond to oxygen. Whether you’re a DIY enthusiast, a student, or simply curious about material science, this article will help you understand why rust and aluminum are more closely linked—and more different—than you might think.

Ever wondered what really happens when aluminum and rust come into contact? The answer lies in chemistry, and it’s more intriguing than you might expect. Let’s break down the science behind the aluminum and rust reaction and see why this process stands out compared to everyday corrosion.

First, let’s clarify what we mean by "rust." Rust is the common term for iron oxide, a reddish-brown compound that forms when iron reacts with oxygen and water. You’ll recognize it as the flaky coating that eats away at old tools and fences. Chemically, rust is most often iron(III) oxide, with the formula Fe2O3. This is important because, in chemistry, the term "rust" is reserved for the oxidation of iron or its alloys—not for aluminum or other metals.

Imagine a ranking of metals based on their eagerness to react—this is called the reactivity series. Aluminum sits higher up than iron, meaning it’s more reactive. In theory, this should make aluminum more likely to oxidize than iron. However, aluminum forms a thin, tough oxide layer (aluminum oxide) almost instantly when exposed to air, which protects it from further corrosion. This is why you rarely see aluminum objects "rusting" in the traditional sense.

Now, what happens if you mix aluminum with rust? Here’s where things get interesting. The rust and aluminum reaction is a classic example of a redox reaction—a process where electrons are transferred between substances. In this case:

In simple terms, aluminum "steals" the oxygen from rust, turning itself into aluminum oxide while reducing the iron oxide back to metallic iron. But here’s the catch: under normal conditions, this reaction is extremely slow. The reason? It requires a significant input of energy to overcome the stable oxide layers on both metals. That’s why, in everyday life, you won’t see aluminum and rust reacting just by sitting next to each other.

Think of activation energy as the spark needed to get a campfire going. For the aluminum and rust reaction, the "spark" comes in the form of intense heat or a strong mechanical force. Without this, the protective oxide layers on both metals act like shields, keeping the reaction in check. Only when enough energy is supplied—such as by heating the mixture with a flame or striking iron and aluminum together with force—does the reaction proceed rapidly, releasing heat and producing molten iron. This is the principle behind the famous thermite reaction, which we’ll explore in the next section (Royal Society of Chemistry).

Curious about what happens when this reaction is unleashed in full force? Next, we’ll dive into the dramatic thermite phenomenon and its real-world applications.

Imagine a reaction so intense that it can melt solid iron and weld railroad tracks in seconds. That’s the awe-inspiring world of the rust and aluminum thermite reaction—a dramatic showcase of chemistry in action. But what makes this process so energetic, and why has it fascinated scientists, engineers, and even pop culture for over a century?

The classic aluminum and rust thermite reaction starts with two simple ingredients: powdered aluminum and iron(III) oxide (Fe2O3), which is the scientific name for rust. When these two powders are mixed thoroughly, they form a stable compound at room temperature. However, the magic happens only when this mixture is ignited with enough heat—often using a magnesium ribbon or a sparkler, as the ignition temperature is extremely high (Wikipedia: Thermite).

Once ignited, the reaction between aluminum and rust is a classic redox (oxidation-reduction) process. Here’s a breakdown of what occurs:

What’s truly remarkable is the energy involved. The reaction is highly exothermic—releasing so much heat (up to around 2200°C or higher) that the iron produced is not just hot, but molten. You’ll notice showers of bright, yellow sparks and even hear a loud crack as the reaction unfolds. These sparks are tiny droplets of molten iron being ejected into the air, instantly oxidizing and emitting light (Harvard Science Demonstrations).

The aluminum and rust thermite reaction isn’t just a laboratory curiosity—it has shaped industries and history:

With such extreme heat, safety is paramount. The reaction can spray molten iron several feet, and once started, it’s nearly impossible to extinguish with water. For this reason, thermite is strictly handled by professionals or under controlled demonstration settings (Harvard Science Demonstrations).

The next time you see a gleaming rail or catch a viral science video, remember: behind the spectacle is the powerful chemistry of aluminum and rust—transforming ordinary materials into molten metal and sparking innovation across industries. Up next, we’ll explore how the physical form of aluminum—powder, foil, or flakes—makes all the difference in thermite’s reactivity and practical use.

When you’re planning a thermite demonstration or industrial weld, have you ever wondered why aluminum powder and rust is the go-to combination? Or why you rarely see people using kitchen foil or metal shavings for these fiery reactions? The answer lies in the science of surface area, ignition, and material consistency.

Imagine crumpling up a sheet of aluminum foil versus holding a handful of fine aluminum dust. Which do you think would react faster with iron oxide? The key difference is surface area. The more surface area exposed, the more places a chemical reaction can start. This is why the physical form of aluminum—whether powder, foil, shavings, dust, or flakes—dramatically changes how it behaves in the thermite process.

| Aluminum Form | Surface Area | Reactivity | Ease of Ignition | Practical Use in Thermite |

|---|---|---|---|---|

| Powder | Very High | Extremely Reactive | Easy (with proper ignition source) | Preferred for thermite reactions; consistent, reliable results |

| Dust | High | Highly Reactive | Easy, but can be hazardous (explosive dust risk) | Sometimes used, but requires careful handling |

| Flakes | Moderate | Moderate | More difficult than powder | Occasionally used, less efficient |

| Shavings | Low | Low | Challenging | Rarely used; slow, unreliable reaction |

| Foil | Very Low | Minimal | Very difficult | Not practical for thermite; mainly used for rust removal, not for ignition |

Aluminum powder is the industry favorite for the thermite process, and for good reason. Its tiny particles maximize surface area, allowing oxygen transfer and electron exchange to happen rapidly. This means the reaction with rust (iron oxide) is not only fast but also fiercely exothermic—producing enough heat to melt iron on the spot (wikihow). Powdered aluminum also mixes evenly with iron oxide, ensuring a uniform reaction and predictable results every time.

What about aluminum foil and rust thermite? While foil is great for household rust removal (as we’ll see later), it’s not suitable for thermite. The low surface area means the reaction is sluggish or may not start at all, even with intense heat. Flakes and shavings offer a bit more surface area but still can’t match the reactivity or ignition reliability of powder or dust. Plus, uneven particle sizes can lead to inconsistent results—never ideal for industrial or safety-critical applications.

In industries where safety and performance are non-negotiable, material consistency is crucial. Companies like Shengxin Aluminum supply high-quality, precisely engineered aluminum products that ensure reliable results in demanding applications. Whether for large-scale welding, manufacturing, or scientific research, using pure, consistent aluminum powder guarantees the thermite process works as intended—every time.

"When you need predictable, high-performance results in thermite reactions or advanced manufacturing, choosing the right aluminum form—and supplier—makes all the difference."

Next, we’ll break down the actual chemistry behind the thermite process, so you can see exactly what’s happening at the atomic level when aluminum and rust collide.

What really happens, atom by atom, when aluminum and rust meet in a thermite reaction? If you’ve ever wondered about the exact aluminum and rust chemical formula that powers this dramatic process, you’re in the right place. Let’s demystify the core chemistry and see why this reaction is so powerful and useful.

At the heart of the thermite reaction is a simple, balanced chemical equation:

2 Al (s) + Fe2O3 (s) → Al2O3 (s) + 2 Fe (l) ΔH = –842.6 kJ/mol

Imagine the equation as a tug-of-war for oxygen atoms. Aluminum, being more reactive than iron, “steals” oxygen from iron oxide. Here’s what’s happening in simple terms:

This is a classic redox reaction—one substance is reduced (gains electrons), and the other is oxidized (loses electrons). The magic of thermite lies in the massive energy shift when aluminum forms its oxide, which is far more stable than iron’s oxide.

The thermite reaction is highly exothermic. In fact, it releases about 842.6 kJ of energy per mole of iron oxide reacted (Chemistry Learner). That’s enough to not only melt the iron produced (melting point 1538°C), but also to keep the reaction going without any outside oxygen—perfect for welding or metal cutting in tough environments.

| Product | Appearance | Role/Significance |

|---|---|---|

| Aluminum Oxide (Al2O3) | White, ceramic-like solid | Forms a protective slag, floats atop molten iron, easy to separate |

| Iron (Fe) | Molten metal | Used for welding, repairs, or metal casting |

So, the next time you see a brilliant burst of sparks from a thermite demonstration, you’ll know: it’s all about aluminum’s hunger for oxygen, the unique chemistry of rust, and a formula that packs a fiery punch. Up next, we’ll shift from high-heat reactions to practical, everyday uses—like how aluminum foil and vinegar can tackle stubborn rust around your home.

When you spot rusty patches on your bike, garden tools, or bathroom fixtures, you might wonder: is there a simple, chemical-free way to restore that shine? Surprisingly, the answer could be as close as your kitchen. Removing rust with vinegar and aluminum foil is a popular DIY hack that’s easy, affordable, and rooted in real chemistry. But what makes this combination so effective—and how can you use it safely on your own metal items?

Let’s break down the science. Rust is iron oxide—a flaky, reddish layer that forms when iron reacts with oxygen and moisture. Vinegar, which contains acetic acid, is a mild acid strong enough to dissolve iron oxide. But that’s only half the story. Aluminum foil acts as both a gentle abrasive and a chemical partner in the process:

The result? You’ll notice the rusty layer fading away, often with visible brown residue transferring onto the foil.

Ready to try this method yourself? Here’s a simple, effective process:

"Aluminum foil is a great cost-effective way to remove rust quickly from metal around your home, however, it is only practical for surface rust and staining, not deeply developed rust, which may require more specialist care." (Homes & Gardens)

This method is a clever, science-backed way to tackle everyday rust, bringing new life to household metal items without harsh chemicals or expensive tools. If you’re curious about even gentler approaches—or want to see how water alone can work with foil—read on for the next simple, effective cleaning hack.

Ever looked at a rusty bike handle or an old car bumper and wondered if there’s a quick, affordable way to restore its shine? Imagine using something as simple as Coca-Cola and aluminum foil—a combination that sounds more like a picnic than a cleaning solution! But as it turns out, the coke and aluminum foil to remove rust trick is a favorite among DIYers for a reason. Let’s break down how this method works, why it’s effective, and how it compares to other common rust-removal hacks.

It may sound surprising, but Coca-Cola contains ingredients that make it a mild rust remover. The key player here is phosphoric acid, a compound that reacts with iron oxide (rust) and helps dissolve it. In addition to phosphoric acid, cola also has citric acid and carbonation, both of which assist in breaking up rust and lifting stains from metal surfaces. While Coca-Cola isn’t as strong as commercial rust removers, it’s a cost-effective, gentle alternative for light to moderate rust spots (CarHop).

Aluminum foil is more than just a kitchen staple—it’s a handy, non-scratching abrasive. When you pair aluminum foil and coke to remove rust, the foil helps physically loosen the rust while the cola’s acids dissolve and soften it. The result? A double-action approach that cleans without damaging most metal finishes.

| Method | Main Active Ingredient | Effectiveness | Best For |

|---|---|---|---|

| Coca-Cola & Aluminum Foil | Phosphoric acid, carbonation | Gentle, slower than commercial removers | Light to moderate surface rust, chrome, household metals |

| Vinegar & Aluminum Foil | Acetic acid | Effective, slightly stronger, may etch some finishes | Light to moderate rust, especially on iron, steel, chrome |

Both methods use mild acids and the gentle abrasion of foil, but vinegar’s acetic acid works a bit faster and can tackle slightly tougher rust. However, cola is less likely to damage delicate finishes and is a fun, accessible option for a quick fix.

While these household hacks are handy, the best solution is to avoid rust altogether. Using corrosion-resistant materials—like high-quality aluminum profiles from trusted manufacturers—means you’ll spend less time cleaning and more time enjoying your metal items. For example, Shengxin Aluminum specializes in advanced aluminum profiles that naturally resist corrosion, making them ideal for windows, doors, and structural applications where durability matters most.

"For lasting protection against rust and less maintenance down the road, choosing corrosion-resistant aluminum profiles is a smart investment."

Curious about even gentler rust removal methods? Next, we’ll explore how water and aluminum foil alone can clean rust without any acids or sodas involved.

Ever noticed light rust creeping onto your favorite chrome fixtures or garden tools and wondered if there’s a gentle, chemical-free way to restore their shine? The answer might be simpler than you think: using aluminum foil and water to remove rust is a surprisingly effective and safe method, perfect for quick touch-ups and delicate surfaces.

At first glance, this hack might seem too simple to work—just water and foil? But there’s real science behind it. When you rub aluminum foil and rust together, two things happen:

This combination means you’re not just scraping rust off—you’re also helping to reverse the oxidation process, all without harsh chemicals or strong acids.

| Step | Action |

|---|---|

| 1 | Tear off a sheet of regular aluminum foil and crumple it into a loose ball. |

| 2 | Dampen the foil with clean water. You can dip it in a bowl or spray water directly onto the foil. |

| 3 | Gently rub the foil over the rusted area, using circular motions. Apply light to moderate pressure—let the foil do the work. |

| 4 | Wipe the surface with a clean, damp cloth to remove loosened rust and residue. |

| 5 | Buff dry with a towel to reveal a brighter, rust-free surface. |

Professional cleaners recommend this method for routine maintenance and quick fixes when you want to avoid strong acids or commercial rust removers. It’s a clever, eco-friendly way to keep your metal items looking their best.

"Aluminum foil is a great cost-effective way to remove rust quickly from metal around your home, however, it is only practical for surface rust and staining, not deeply developed rust, which may require more specialist care." (Homes & Gardens)

Curious about why aluminum itself doesn’t rust like iron? For a deeper dive into the science of aluminum corrosion and why it’s so resistant, check out this comprehensive guide: Does Aluminum Rust? Unveiling the Surprising Truth.

Next, we’ll compare how aluminum’s unique oxidation process differs from traditional iron rusting—and why this matters for your next project or purchase.

When you leave a steel tool outside or spot a dull patch on aluminum siding, you might wonder: are both metals rusting in the same way? The answer is more nuanced—and understanding the distinction between rust and aluminum oxidation is crucial for choosing the right materials and maintenance strategies.

Let’s start with the basics. Rust is the flaky, reddish-brown substance you see on iron and steel when they’re exposed to water and oxygen. In scientific terms, rust is iron oxide (Fe2O3), and it forms as iron atoms bond with oxygen, breaking down the metal’s structure over time. This process is unique to iron and its alloys—so while you might hear people say that aluminum “rusts,” that’s not technically correct.

Aluminum, on the other hand, undergoes oxidation rather than rusting. When exposed to air, aluminum reacts with oxygen to form a thin, hard layer of aluminum oxide (Al2O3). Here’s the twist: instead of flaking away and exposing fresh metal, this oxide layer clings tightly to the aluminum’s surface, effectively sealing and protecting the underlying metal from further corrosion (Kloeckner Metals).

So, what makes aluminum oxidation so effective, and why does iron rust keep eating away at steel? It comes down to the properties of the oxide layers themselves. Let’s break it down:

| Feature | Aluminum Oxidation | Iron Rusting |

|---|---|---|

| Chemical Formula | Al2O3 (Aluminum Oxide) | Fe2O3 (Iron(III) Oxide) |

| Appearance | Thin, hard, whitish or dull gray film | Flaky, reddish-brown or orange coating |

| Porosity | Non-porous, dense | Porous, allows moisture/oxygen through |

| Adherence | Strongly bonded to metal surface | Weakly attached, flakes off easily |

| Protective Qualities | Prevents further corrosion; self-healing if scratched | Exposes fresh metal; corrosion continues underneath |

When deciding between aluminum and steel rust resistance, the difference is clear:

For applications like window frames, siding, marine hardware, or vehicles, aluminum’s self-protecting nature often makes it a smarter, lower-maintenance choice. However, in extreme environments (like those with high chloride or salt exposure), even aluminum may need extra protection.

"Aluminum doesn’t rust the way iron does. Its unique oxide layer is nature’s built-in defense, making it one of the most corrosion-resistant metals for everyday use."

Next, we’ll wrap up by summarizing the key lessons about aluminum’s unique relationship with rust and why material selection matters for long-term durability.

When you think back on everything we’ve explored about aluminum and rust, you’ll notice just how unique—and practical—aluminum’s behavior is compared to iron and steel. Whether you’re fascinated by the fiery spectacle of the thermite reaction or searching for simple ways to keep your metal items rust-free, understanding how these materials interact can guide smarter choices for both DIY projects and industrial applications.

Imagine you’re designing a new structure, choosing window frames, or selecting components for a vehicle or appliance. Would you rather spend years battling rust, or opt for a material that naturally resists it? That’s where the science of aluminum truly shines. Not only is aluminum lightweight and strong, but its corrosion resistance also means fewer repairs and replacements over time.

For industries and projects where durability, safety, and low maintenance are priorities, high-quality aluminum profiles make a world of difference. Manufacturers like Shengxin Aluminum specialize in advanced, corrosion-resistant aluminum solutions—ideal for everything from architectural facades to rail transit and energy-efficient windows. Choosing the right material at the outset can save time, money, and hassle for years to come.

"Understanding the science behind aluminum and rust empowers you to make smarter, longer-lasting choices—whether you’re cleaning up a rusty tool or building the next generation of infrastructure."

By prioritizing material science and investing in quality, corrosion-resistant aluminum, you’ll ensure your projects stand the test of time—no matter what challenges the environment may bring.

Aluminum can react with rust (iron oxide) in a process known as the thermite reaction. When powdered aluminum is combined with rust and ignited at high temperatures, it produces molten iron and aluminum oxide. However, under normal conditions, this reaction does not occur spontaneously due to protective oxide layers on both metals.

Aluminum does not rust in the traditional sense because rust refers specifically to iron oxide. Instead, aluminum forms a thin, protective layer of aluminum oxide when exposed to oxygen. This layer shields the metal from further corrosion, making aluminum highly resistant to environmental damage.

Aluminum will not rust if it gets wet, as rust is specific to iron-containing metals. When aluminum is exposed to water, it quickly forms a stable aluminum oxide layer that protects it from further corrosion. This makes aluminum a preferred choice for outdoor and humid environments.

Aluminum does not rust at all, as it contains no iron. Instead, it forms a durable oxide layer almost instantly when exposed to air or moisture, providing long-term protection against corrosion. Only in highly aggressive environments will aluminum show signs of surface deterioration.

Aluminum oxidation produces a thin, dense, and self-healing aluminum oxide layer that adheres tightly to the metal, preventing further corrosion. In contrast, iron rusting creates a flaky, porous iron oxide that exposes fresh metal, allowing ongoing deterioration. This key difference explains why aluminum remains durable while iron can degrade over time.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360