Imagine a material so versatile that it forms the backbone of countless structures across various industries. This is exactly what the 40x40 aluminum extrusion profile offers. As a key component in modular framing systems, this profile is integral to creating adaptable and efficient frameworks. But what exactly makes the 40x40 aluminum extrusion so significant?

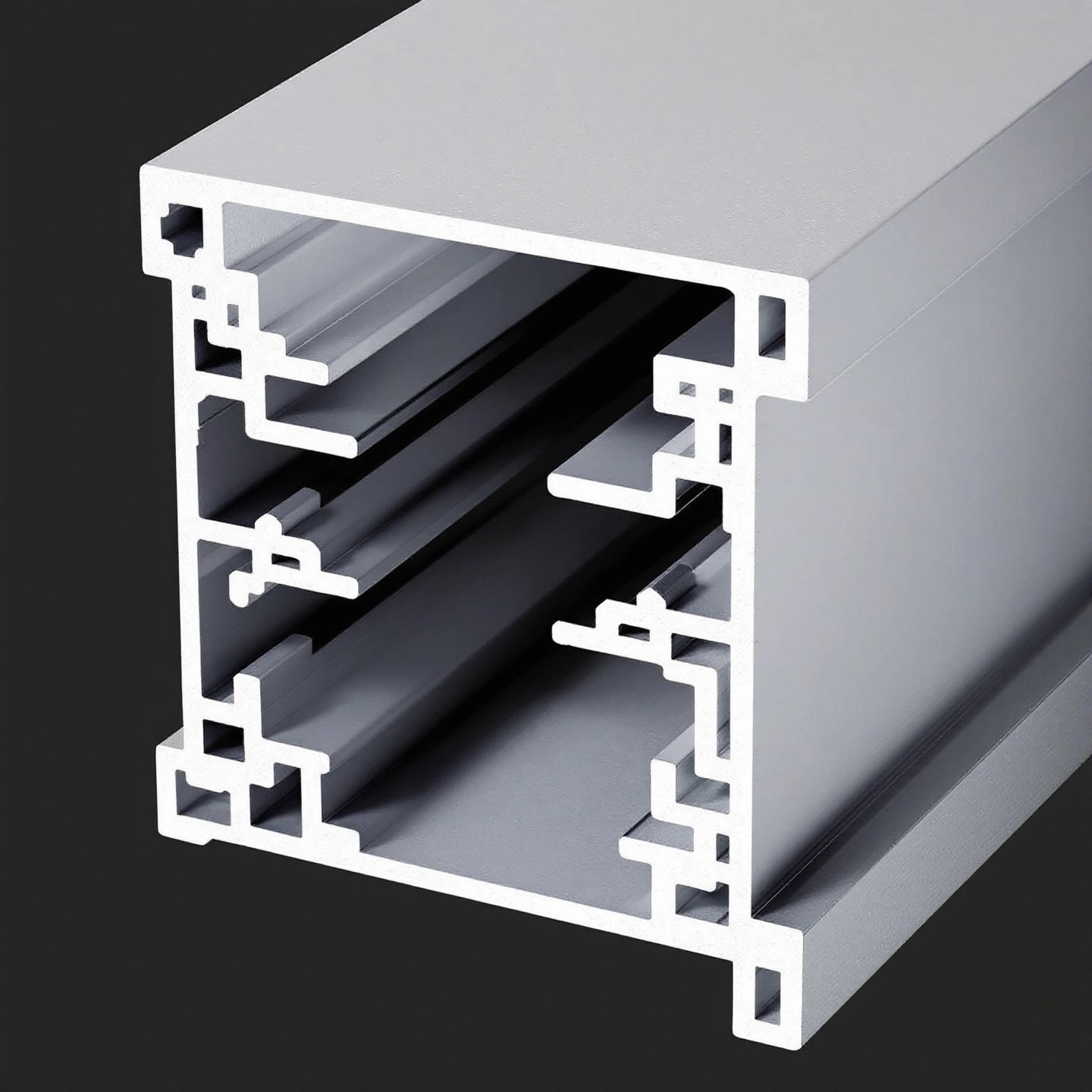

At its core, the 40x40 aluminum extrusion is a square profile measuring 40mm by 40mm. Its design is not only about simplicity but also about strength and versatility. This profile is crafted from high-quality aluminum, known for its excellent strength-to-weight ratio, making it a preferred choice in industries ranging from automation to construction. The structural benefits of this profile are immense, providing a robust yet lightweight solution for creating everything from machine guards to intricate workstations.

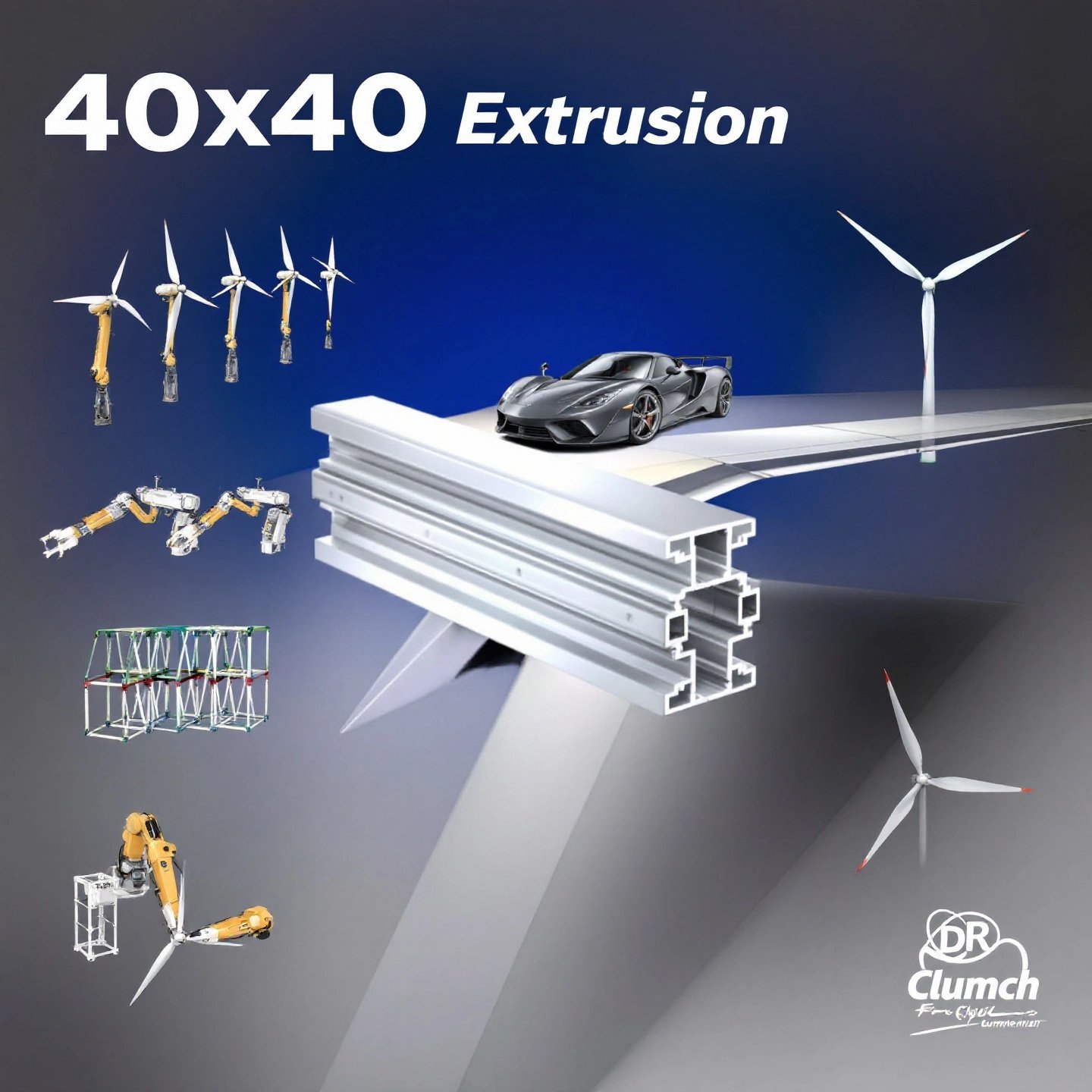

Aluminum extrusions like the 40x40 profile play a crucial role in various sectors. In industrial settings, they are used to build frameworks for machinery, ensuring durability and ease of assembly. In the consumer sector, they contribute to the design of lightweight yet sturdy furniture and fixtures. The aerospace and automotive industries also rely heavily on aluminum extrusions to reduce weight without compromising strength, enhancing fuel efficiency and performance.

With its standard dimensions, the 40x40 aluminum extrusion facilitates easy integration with other components and accessories, enabling endless customization possibilities. Whether you're looking to construct a new factory line or a bespoke piece of furniture, this profile offers a reliable foundation.

In summary, the 40x40 aluminum extrusion is more than just a building material; it's a cornerstone of modern design and engineering, providing flexibility, strength, and efficiency across a multitude of applications.

When considering the 40x40 aluminum extrusion for your next project, it's crucial to understand its technical specifications and inherent features that make it a standout choice in modular framing systems. These extrusions are crafted from 6063-T6 aluminum, a material renowned for its excellent mechanical properties and corrosion resistance. This alloy is not only lightweight but also provides a robust structural integrity, making it ideal for a variety of applications.

The 40x40 aluminum extrusion is made from 6063-T6 aluminum, which includes elements like magnesium and silicon to enhance its strength and durability. This composition results in a tensile strength of at least 30,000 psi and a yield strength of 25,000 psi, ensuring that the extrusion can withstand significant stress without deforming. Additionally, the extrusion's modulus of elasticity is approximately 10,000,000 lbs/sq in, providing the necessary rigidity for structural applications.

Dimensionally, the 40x40 profile is precisely 40mm by 40mm, offering a symmetrical structure that simplifies alignment and integration into existing systems. Each profile features four 8mm T-slots, which facilitate easy attachment of accessories and connectors, enhancing its modularity. The center-bore is ready to be tapped with M8 or 5/16-18 threads, allowing for versatile assembly options.

Surface finish options further enhance the utility of the 40x40 aluminum extrusion. A common choice is clear anodizing, which not only improves corrosion resistance but also provides a sleek, professional appearance. Anodizing involves an electrochemical process that thickens the natural oxide layer on the aluminum, offering enhanced protection against environmental factors.

In summary, the 40x40 aluminum extrusion combines material excellence with precise engineering to deliver a versatile and reliable component for modular systems. Its specifications ensure it meets the rigorous demands of industrial and commercial applications, while its features provide the flexibility needed for innovative designs.

When you think of building versatile and robust structures, the 40x40 aluminum extrusion profile stands out as a key player. Its adaptability and strength make it a favorite in numerous sectors. But where exactly does this profile shine the most? Let's delve into the diverse applications of the 40x40 aluminum extrusion.

In industrial settings, the 40x40 aluminum extrusion is a go-to choice for constructing machine guards, workstations, and enclosures. Its sturdy design and ease of assembly allow for quick installation and reconfiguration, which is crucial in dynamic manufacturing environments. The profile's compatibility with various connectors and accessories facilitates the creation of custom automation frameworks and robotic assemblies, enhancing productivity and safety in factories.

Aluminum extrusions are integral to the field of automation and robotics. The 40x40 profile is often used in the construction of automation frameworks and robotic assemblies, providing a lightweight yet strong foundation. This is particularly beneficial in applications where precision and stability are paramount, such as in the assembly of robotic arms or the creation of conveyance systems. According to Evolution Motion , aluminum extrusions like these are pivotal in creating ergonomic workspaces and optimizing production lines.

For the DIY enthusiast or hobbyist, the 40x40 aluminum extrusion opens up a world of possibilities. Its modular nature makes it perfect for custom projects ranging from home improvement tasks to innovative furniture designs. Whether you're building a custom shelving unit or a mobile workbench, this profile provides the flexibility and durability needed to bring your ideas to life. Resources like 80/20's Xtreme DIY series offer inspiration and guidance for utilizing T-slot aluminum profiles in creative ways.

In summary, the 40x40 aluminum extrusion is not just a component; it's a versatile solution that meets the needs of various industries and projects. From enhancing industrial automation to facilitating creative DIY endeavors, this profile proves to be an invaluable asset. As you explore your next project, consider the endless potential that the 40x40 aluminum extrusion offers, supported by the extensive product range and innovation commitment of companies like Shengxin Aluminum.

When it comes to selecting materials for structural projects, the 40x40 aluminum extrusion stands out due to its myriad advantages. But what makes it such a compelling choice? Let's explore the key benefits that this profile offers.

One of the most significant advantages of the 40x40 aluminum extrusion is its exceptional strength-to-weight ratio. Aluminum is about one-third the weight of steel, yet it maintains impressive strength characteristics. This makes it an ideal choice for applications where reducing weight is crucial, such as in aerospace and automotive industries. The ability to maintain structural integrity while minimizing weight contributes to enhanced fuel efficiency and performance.

Aluminum naturally forms a protective oxide layer that guards against corrosion, making the 40x40 aluminum extrusion highly durable in various environments. This resistance is further enhanced through anodizing, a process that thickens the oxide layer, providing additional protection and a sleek finish. As a result, these extrusions are well-suited for outdoor applications and environments prone to moisture or chemical exposure.

The modular nature of the 40x40 aluminum extrusion simplifies assembly and customization. Its design allows for easy integration with other components, using T-slots that accommodate a variety of connectors and accessories. This flexibility is particularly beneficial in projects requiring frequent modifications or expansions, such as in manufacturing setups or custom DIY projects.

Moreover, the ease of assembly reduces installation time and labor costs, making aluminum extrusions a cost-effective solution for both large-scale industrial applications and small-scale personal projects.

In conclusion, the 40x40 aluminum extrusion offers a combination of strength, durability, and versatility that is hard to match. Its ability to withstand harsh conditions while providing flexible design options makes it an invaluable resource for engineers and DIY enthusiasts alike. As you plan your next project, consider the advantages of this robust and adaptable material.

Designing with 40x40 aluminum extrusion can be both exciting and challenging. Whether you're constructing a simple frame or a complex machine assembly, understanding the key design considerations is crucial to ensure your structure is both robust and efficient.

When it comes to load-bearing capabilities, the 40x40 aluminum extrusion offers impressive strength. However, proper calculations are essential to ensure safety and functionality. According to PBA Leader Motion , it's crucial to consider the allowable load values, which depend on the profile length and deflection limits. For example, a 40x40 profile with a length of 1000mm can handle a load of up to 321 N with a deflection of 1mm. Always aim to keep the load within these limits to avoid structural failures.

The modular nature of aluminum extrusions allows for a wide range of connector options. From T-slot connectors to corner brackets, choosing the right connector is vital for stability and ease of assembly. As noted by Framing Tech , the use of T-slot connectors simplifies the assembly process, eliminating the need for welding or grinding. Ensure that the connectors you select are compatible with the 40x40 profile dimensions and the specific requirements of your project.

Environmental factors can significantly impact the performance of your aluminum extrusion structures. Aluminum's natural corrosion resistance is enhanced through anodizing, making it suitable for outdoor and harsh environments. Additionally, consider the environmental impact of your design. As highlighted by the Aluminum Extruders Council , using recycled aluminum can significantly reduce carbon emissions and energy consumption. Opting for sustainable materials and practices not only benefits the environment but can also enhance the longevity and sustainability of your project.

In summary, designing with 40x40 aluminum extrusion requires careful consideration of load-bearing capabilities, connector compatibility, and environmental factors. By paying attention to these aspects, you can create structures that are not only functional and durable but also environmentally responsible.

When it comes to assembling structures with 40x40 aluminum extrusions, the process is as straightforward as it is rewarding. But where do you start, and what should you keep in mind to ensure a smooth assembly? Let's dive into some essential tips and best practices.

Before you begin, make sure you have the right tools on hand. The basics include Allen wrenches, a metal cutting saw, and a drill for any additional holes you might need. Depending on your project, you might also require a tapping tool for threading holes and a measuring tape for precision cuts. Having these tools ready will streamline your assembly process and help avoid unnecessary delays.

1. Plan Your Layout: Begin by drafting a detailed plan of your structure. This will help you visualize the final product and identify the components and connectors you need.

While assembling 40x40 aluminum extrusions is generally straightforward, there are a few common pitfalls to watch out for:

With these assembly tips and best practices, you'll find that working with 40x40 aluminum extrusions is not only efficient but also highly rewarding. The ease of assembly and the flexibility of these extrusions make them an excellent choice for a wide range of projects. As you finalize your assembly, you'll be ready to explore the maintenance practices that will ensure the longevity of your aluminum structures.

Ensuring the longevity of 40x40 aluminum extrusion structures involves a proactive maintenance approach. Regular upkeep not only preserves the aesthetic appeal of your structures but also extends their functional lifespan. So, how can you effectively maintain these versatile profiles?

Regular inspections are vital for identifying early signs of wear and tear. During these checks, pay attention to joints, seams, and connection points, as these are prone to damage. Look for any dents, scratches, or signs of corrosion, especially in outdoor installations where environmental factors play a significant role. According to ASA Aluminum , regular cleaning is equally important. Use a mild detergent mixed with water and a soft-bristle brush to gently remove dirt and debris. Avoid harsh chemicals or abrasive materials that can scratch or corrode the aluminum surface.

Applying protective coatings can significantly enhance the resistance of aluminum structures to corrosion. Options such as clear sealants, paint, or powder coatings provide a layer of protection while allowing for aesthetic customization. As highlighted by JM Aluminium , anodizing is a popular choice that not only enhances corrosion resistance but also maintains the natural luster of the aluminum.

Environmental factors can affect the longevity of aluminum structures. For outdoor applications, consider the impact of weather conditions and take measures to mitigate exposure to harsh elements. Proper drainage and protection from extreme weather can help preserve the quality of the aluminum profiles.

Even with regular maintenance, wear and tear can occur. Minor scratches or marks can often be addressed with touch-up techniques or professional restoration services. Ensure that any repairs maintain the integrity of the structure without compromising its protective properties.

In conclusion, maintaining aluminum extrusion structures requires consistent attention and care. By following these practices, you can ensure that your 40x40 aluminum structures not only look great but also perform optimally for years to come. As you focus on maintaining aluminum extrusion, you'll be well-prepared to explore the innovations and future trends shaping this versatile material.

As the aluminum extrusion industry continues to evolve, several emerging trends and technological advancements are shaping its future. These innovations are not only enhancing the efficiency and sustainability of aluminum extrusion processes but also redefining design possibilities. So, what are these trends, and how are they impacting the industry?

One of the most significant trends in aluminum extrusion is the push towards sustainability. Companies are increasingly adopting lean management practices to minimize waste and improve production efficiency. According to PSI Extrusions , advanced techniques such as automation and AI are being leveraged to reduce CO2 emissions and energy consumption. For instance, automating processes like skimming and scrap charging has been shown to cut cycle times by up to 50% and decrease CO2 generation by 30%.

Smart technologies, including AI and IoT, are increasingly integrated into aluminum extrusion processes. These technologies provide real-time monitoring and predictive analytics, which enhance quality control and operational efficiency. AI-driven solutions like HyperAI enable the production of high-strength extruded profiles with improved speed and precision. Moreover, the use of digital twins allows manufacturers to simulate production scenarios, optimizing performance before physical production begins, as noted by Metals Mining Review .

The development of new aluminum alloys and composite materials is another key trend. These materials offer enhanced strength, corrosion resistance, and machinability, making them suitable for demanding applications. Additionally, advancements in surface finishing techniques, such as nano-coatings and self-healing materials, are improving the durability and aesthetic appeal of aluminum extrusions.

For a comprehensive guide on mastering the aluminum alloy extrusion process, you can explore Shengxin Aluminum's guide .

In conclusion, the future of aluminum extrusion is bright, with sustainability, smart technologies, and innovative materials leading the way. These advancements are ensuring that aluminum extrusion remains a vital component in modern manufacturing, offering endless possibilities for design and application.

In the ever-evolving landscape of modern design and engineering, the 40x40 aluminum extrusion continues to hold its ground as a versatile and indispensable component. Its unique blend of strength, lightweight properties, and adaptability makes it a preferred choice across numerous industries, from automotive to aerospace, and from industrial automation to DIY projects.

The 40x40 aluminum extrusion's ability to integrate seamlessly into modular systems is one of its standout features. This profile's adaptability ensures it can meet the demands of both simple and complex structures, providing a solid foundation for innovation and creativity. Whether you're constructing a high-tech automation framework or a custom piece of furniture, this extrusion offers the flexibility and durability needed to bring your vision to life.

Moreover, companies like Shengxin Aluminum are leading the charge in advancing aluminum extrusion technology. Shengxin's commitment to quality and innovation, as highlighted by their extensive product range and advanced manufacturing capabilities, ensures that they remain at the forefront of the industry. Their dedication to sustainable practices and cutting-edge technology positions them as a key player in the future of aluminum extrusion.

As you consider your next project, remember the 40x40 aluminum extrusion for its unparalleled versatility and reliability. Its role in modern engineering is not just about meeting current needs but also about paving the way for future advancements. Shengxin Aluminum's products exemplify this forward-thinking approach, offering solutions that are not only efficient and robust but also aligned with the latest industry trends.

In conclusion, the 40x40 aluminum extrusion is more than just a structural component; it is a testament to the possibilities of modern engineering. Its enduring relevance and adaptability make it an essential element in the toolkit of engineers, designers, and innovators worldwide. Embrace the future of design with the 40x40 aluminum extrusion and explore the vast potential it holds for your projects.

The 40x40 aluminum extrusion is crafted from 6063-T6 aluminum, offering a strong yet lightweight structure with excellent corrosion resistance. It includes four 8mm T-slots for easy assembly and customization, making it ideal for diverse applications.

In industrial settings, 40x40 aluminum extrusion is used for constructing machine guards, workstations, and enclosures. Its modularity allows for quick reconfiguration and integration with various automation frameworks and robotic assemblies.

The 40x40 aluminum extrusion offers a high strength-to-weight ratio, excellent corrosion resistance, and modularity. These features make it suitable for a wide range of applications, from aerospace to DIY projects.

Regular inspections and cleaning with mild detergent can prolong the life of aluminum extrusion structures. Applying protective coatings like anodizing enhances corrosion resistance, ensuring long-term durability.

Sustainable manufacturing practices, smart technologies, and new alloy developments are key trends. These innovations enhance efficiency, reduce environmental impact, and expand design possibilities in aluminum extrusion.

Інтернет-сервіс

Інтернет-сервіс 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360